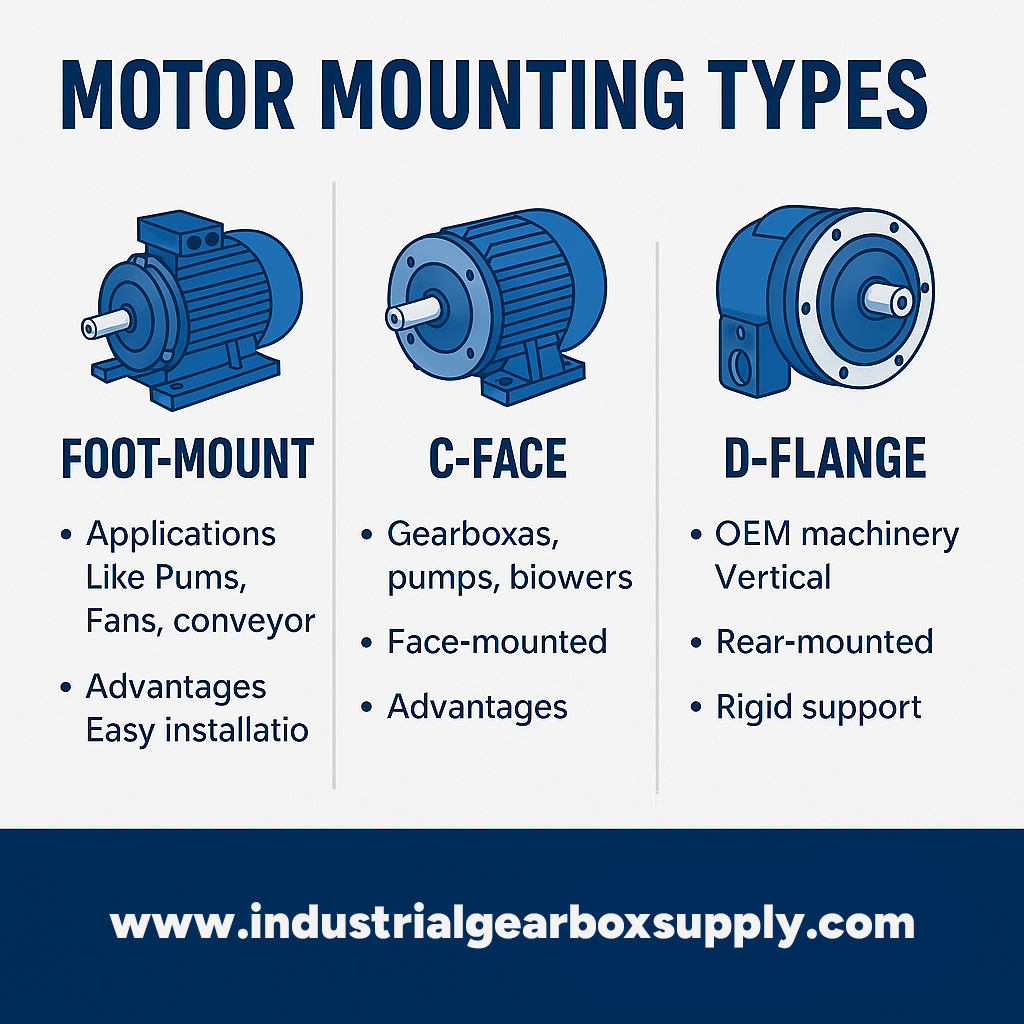

Motor Mounting Types: Foot-Mount, C-Face, and D-Flange

Selecting the correct motor mounting type is crucial for ensuring proper fit, alignment, and reliability in your application. ABB NEMA motors are available in various mounting configurations—each designed for specific installation environments.

In this guide, we’ll cover the three most common types: Foot-Mount, C-Face, and D-Flange, and help you choose the right one for your equipment.

1. What is a Motor Mounting Type?

A motor mounting type refers to how the electric motor is physically secured to the equipment it powers. This affects alignment, vibration control, maintenance access, and interchangeability. NEMA (National Electrical Manufacturers Association) defines standard mounting configurations to ensure compatibility across brands.

2. Foot-Mount Motors (B3 or B5/B3 Hybrid)

Also called base-mounted motors, foot-mount motors come with a sturdy base that bolts directly to a surface.

✅ Applications: Pumps, fans, conveyors, compressors

✅ Advantages: Easy to install, simple alignment, widely available

✅ Typical ABB NEMA Designation: B3 or hybrid B5/B3

When to Use:

Use foot-mounted motors when space allows and when horizontal mounting is preferred. Ideal for stable, vibration-free installations.

3. C-Face Motors (NEMA C-Face Mount)

C-Face motors feature a machined circular faceplate with bolt holes for flange mounting and a protruding shaft for direct coupling.

✅ Applications: Gearboxes, pumps, blowers, machine tools

✅ Advantages: Precise alignment, compact size, fast installation/removal

✅ NEMA Designation: NEMA C-Face (e.g., 56C)

When to Use:

Use C-Face motors for close-coupled systems where shaft alignment is critical and space is limited.

4. D-Flange Motors (NEMA D-Flange or FF Flange)

D-Flange motors have a similar concept to C-Face motors but are typically mounted from the back side (rear flange). These are less common but essential in certain OEM applications.

✅ Applications: OEM machinery, vertical mounting

✅ Advantages: Rear-face installation, rigid support, vertical use

✅ NEMA Designation: D-Flange (also known as FF Flange)

When to Use:

Choose D-Flange motors when your equipment requires rear-mounting or vertical orientation with a compact footprint.

5. Quick Comparison Table

| Feature | Foot-Mount | C-Face | D-Flange |

|---|---|---|---|

| Mounting Style | Base bolted | Face bolted (front) | Flange bolted (rear) |

| Alignment | Manual | Precise | Precise |

| Common Uses | Fans, conveyors | Pumps, gearboxes | Vertical machinery |

| Removal | More effort | Quick | Medium |

| ABB Motor Code | B3, B5/B3 | 56C, 143TC, etc. | FF Flange |

6. ABB NEMA Motors: Flexible Mounting Options

ABB offers its Baldor-Reliance and standard NEMA motors in various mounting configurations to meet your operational needs. Many models are dual-mount or adaptable, reducing inventory costs and simplifying installation.

7. Choosing the Right Mount for Your Application

Ask these questions when selecting a mount type:

Will it be mounted horizontally or vertically?

Is shaft alignment critical?

Do you need fast motor replacement?

Is space limited?

If you’re unsure, Industrial Gearbox Supply can help identify the correct motor mounting type based on your machinery and environment.

Next Steps

Choosing the right motor mounting type ensures longer equipment life, reduced downtime, and easier maintenance. Whether you need a simple foot-mount motor or a precision C-face unit, ABB NEMA motors offer the right configuration for your needs.

To figure out what motors and gearboxes you need, contact us:

📞 (517) 858-2966

📧 sales@industrialgearboxsupply.com

🌐 www.industrialgearboxsupply.com

🏢 3590 Scheele Dr, Jackson, MI 49202