Explosion Proof Motors: What They Are, How They Work, and Where to Use Them

In industrial environments where flammable gases, vapors, or dust may be present, safety is paramount. That’s where explosion proof motors come in. These motors are built to contain internal explosions and prevent external ignition—making them essential in oil refineries, chemical plants, mining operations, and grain handling facilities.

This article explains how explosion proof motors work, why they matter, and how to choose the right one based on class, division, and group designations.

What Is an Explosion Proof Motor?

An explosion proof motor is a totally enclosed motor designed to withstand an internal explosion of a flammable gas or vapor—and prevent the explosion from igniting the surrounding atmosphere.

They’re certified for hazardous locations and meet strict NEMA and UL standards. Explosion proof motors don’t prevent explosions inside the motor—they’re designed to contain the blast and safely vent it without igniting the external environment.

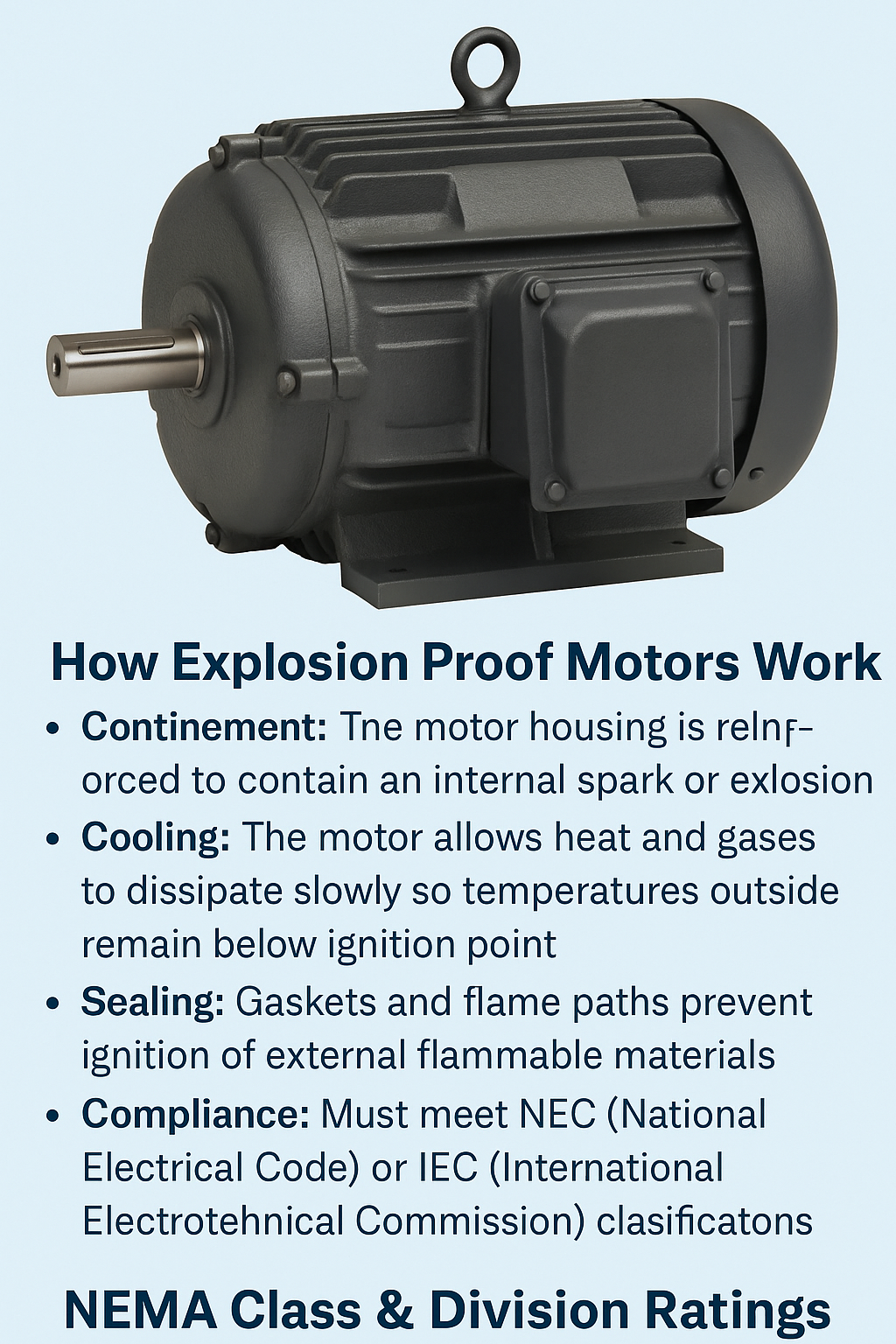

How Explosion Proof Motors Work

Containment: The motor housing is reinforced to contain an internal spark or explosion.

Cooling: The motor allows heat and gases to dissipate slowly so temperatures outside remain below ignition point.

Sealing: Gaskets and flame paths prevent ignition of external flammable materials.

Compliance: Must meet NEC (National Electrical Code) or IEC (International Electrotechnical Commission) classifications.

NEMA Class & Division Ratings for Explosion Proof Motors

| Class | Division | Description |

|---|---|---|

| Class I | Division 1 | Flammable gases/vapors present under normal conditions |

| Class I | Division 2 | Flammable gases present under abnormal conditions only |

| Class II | Division 1 | Combustible dusts present under normal operation |

| Class II | Division 2 | Combustible dusts present under abnormal conditions |

| Class III | Divisions 1 & 2 | Ignitable fibers or flyings (e.g., textile mills, woodworking) |

Common Applications for Explosion Proof Motors

Explosion proof motors are essential in areas where volatile materials are handled, processed, or stored.

| Industry | Application |

|---|---|

| Oil & Gas | Pumps, compressors, drilling rigs |

| Chemical | Mixers, agitators, blowers |

| Mining | Conveyors, crushers, dust collectors |

| Food & Grain | Grain elevators, flour mills, storage silos |

| Paint & Coatings | Spray booths, solvent processing |

Key Features to Look For

When selecting an explosion proof motor, consider:

Certified Class/Division rating

Voltage and HP requirements

Mounting style (C-face, foot mount, etc.)

Enclosure type (XP, TEFC XP)

Manufacturer certifications (UL, CSA, ATEX)

Ambient temperature & duty cycle

Why Choose ABB Explosion Proof Motors?

ABB offers a complete line of Class I and II explosion proof motors built to NEMA standards. With superior housing strength, energy-efficient designs, and full UL/CSA certifications, ABB motors are trusted across critical hazardous industries worldwide.

Get Explosion Proof Motors from Industrial Gearbox Supply

If safety is your priority, we carry ABB explosion proof motors that meet Class I, Class II, and Class III standards for hazardous locations. Our experts will help you find the right motor to match your compliance and performance needs.

Contact us today:

Phone: (517) 858-2966

Email: sales@industrialgearboxsupply.com

Website: industrialgearboxsupply.com

Location: 3590 Scheele Dr, Jackson, MI 49202