Backlash in Gearboxes: What It Is and Why It Matters

Backlash is a normal but often misunderstood characteristic of gearboxes. While some amount of backlash is necessary for proper operation, excessive backlash can lead to noise, positioning errors, vibration, and premature wear.

Understanding what backlash is, why it exists, and how it affects performance is critical when selecting, installing, or troubleshooting an industrial gearbox.

What Is Backlash in a Gearbox?

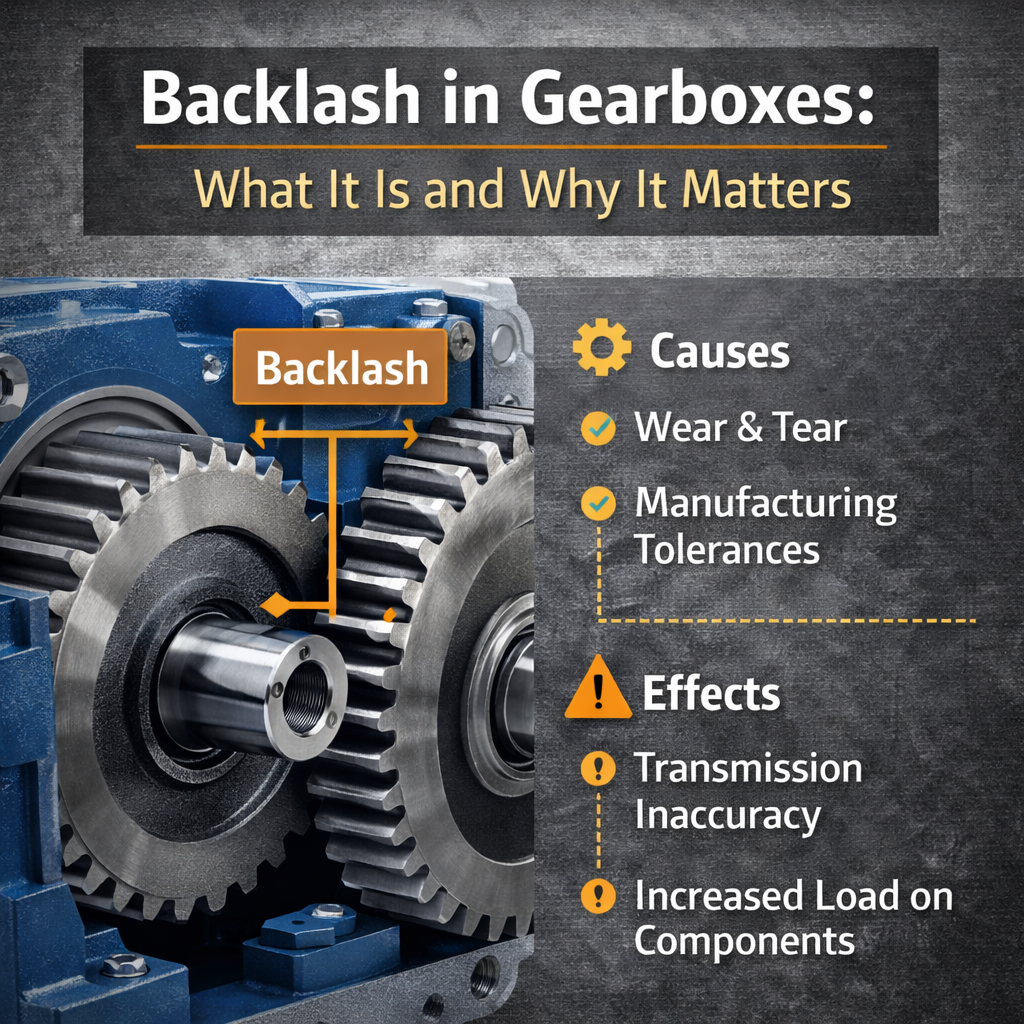

Backlash is the amount of free movement between mating gear teeth when the direction of rotation changes.

In simple terms, it is the small gap between gear teeth that allows gears to rotate without binding.

When you reverse the direction of a gearbox output shaft and feel a slight delay before motion transfers, that movement is backlash.

Why Backlash Exists

Backlash is intentionally designed into gearboxes for several reasons.

Gears need clearance to:

Allow proper lubrication between teeth

Prevent binding due to thermal expansion

Compensate for manufacturing tolerances

Enable smooth rotation under load

A gearbox with zero backlash would quickly overheat, wear rapidly, and likely fail.

Acceptable vs Excessive Backlash

All gearboxes have some backlash, but not all backlash is acceptable.

Acceptable backlash depends on:

Gearbox type

Gear size and pitch

Application requirements

Load direction and duty cycle

Excessive backlash occurs when clearances exceed design limits due to wear, damage, or improper setup.

How Backlash Affects Performance

Backlash impacts gearbox performance in several ways.

Noise and Shock Loading

When load direction changes, backlash allows gears to impact each other before fully engaging. This impact creates noise and shock loading, which accelerates wear.

Frequent reversing applications are especially sensitive to backlash.

Positioning Accuracy

In applications such as indexing tables, robotics, or conveyors with precise positioning, backlash causes lost motion.

This lost motion reduces accuracy and repeatability.

Vibration

Excessive backlash contributes to vibration as gears repeatedly engage and disengage under load.

Vibration further accelerates bearing and gear wear.

Wear and Fatigue

As backlash increases, load distribution across gear teeth becomes uneven. This leads to localized stress, surface pitting, and fatigue cracking.

Over time, this wear increases backlash even more, creating a compounding problem.

Backlash by Gearbox Type

Different gearbox designs inherently have different backlash characteristics.

Helical and bevel gearboxes typically have moderate backlash suitable for most industrial applications.

Planetary gearboxes are designed with low backlash and are commonly used where positioning accuracy is important.

Worm gearboxes often have higher backlash, especially at higher ratios, due to gear geometry and wear patterns.

Understanding the gearbox type helps set realistic backlash expectations.

Common Causes of Excessive Backlash

Excessive backlash usually develops over time rather than appearing suddenly.

Common causes include:

Gear tooth wear

Bearing wear allowing shaft movement

Improper gear setup or preload

Misalignment

Overloading or shock loads

Insufficient or contaminated lubrication

Backlash increase is often a symptom of a deeper mechanical issue.

How Backlash Is Measured

Backlash can be measured by:

Rotating the output shaft back and forth with the input locked

Using dial indicators to measure angular or linear movement

Comparing movement to manufacturer specifications

Accurate measurement helps determine whether backlash is within acceptable limits.

Backlash vs Gear Wear

Backlash and gear wear are closely related but not identical.

Some backlash is designed into the gearbox. Gear wear increases backlash beyond design limits.

When backlash continues to increase over time, it usually indicates progressive wear rather than a one-time setup issue.

When Backlash Becomes a Problem

Backlash becomes a problem when it affects:

Process control

Positioning accuracy

Noise levels

Equipment reliability

Product quality

Applications with frequent starts, stops, or reversals are most sensitive to excessive backlash.

Can Backlash Be Adjusted?

In some gearboxes, backlash can be adjusted through:

Bearing preload adjustment

Shim changes

Gear repositioning

However, many industrial gearboxes are not designed for field backlash adjustment.

In these cases, excessive backlash often means the gearbox requires rebuild or replacement.

Reducing the Impact of Backlash

While backlash cannot be eliminated, its impact can be reduced by:

Selecting low-backlash gearbox designs where needed

Maintaining proper lubrication

Avoiding shock loading

Ensuring proper alignment

Monitoring wear through inspection and vibration analysis

Proper application matching is the most effective way to control backlash-related issues.

Backlash and Gearbox Selection

When selecting a gearbox, backlash requirements should be considered alongside torque, speed, and service factor.

Choosing a gearbox with unnecessarily tight backlash increases cost without benefit.

Choosing a gearbox with excessive backlash for a precision application leads to poor performance.

Matching backlash to application needs ensures reliable operation.

Final Thoughts

Backlash is a necessary part of gearbox operation, but excessive backlash signals wear, misalignment, or improper application.

Understanding what backlash is and why it matters helps prevent noise, vibration, and premature gearbox failure.

If you need help evaluating backlash issues or selecting a gearbox with the correct backlash characteristics, IndustrialGearboxSupply.com can help guide you toward the right solution.