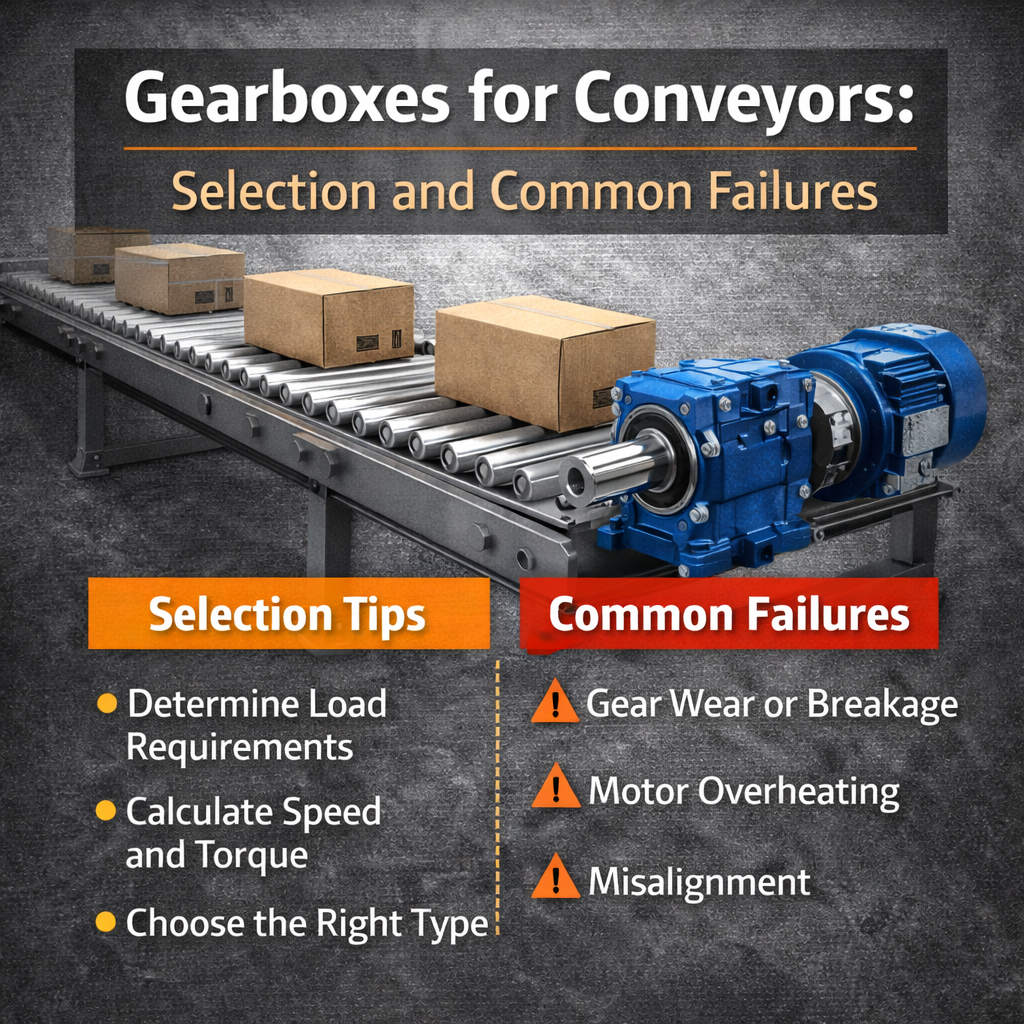

Gearboxes for Conveyors: Selection and Common Failures

Conveyors are one of the most common industrial applications for gearboxes, yet they are also one of the most frequently misapplied. Incorrect gearbox selection is a leading cause of conveyor downtime, excessive wear, and premature failure.

This article explains how to properly select gearboxes for conveyors and outlines the most common failure modes seen in real-world conveyor systems.

Why Conveyor Gearbox Selection Matters

Conveyors operate under unique conditions compared to many other driven systems.

They often experience:

Continuous duty cycles

Heavy loads

Frequent starts and stops

Shock loading

Overhung loads from pulleys or sprockets

A gearbox that is incorrectly sized or poorly matched to these conditions will fail far sooner than expected.

Key Factors When Selecting a Gearbox for Conveyors

Proper selection starts with understanding the conveyor’s operating requirements.

Required Output Speed

The required output speed is determined by belt speed, roller diameter, or chain pitch.

Conveyor speed must be calculated accurately before selecting a gearbox ratio. Overspeeding can cause material spillage, while underspeeding reduces throughput.

Torque Requirements

Conveyors often require high starting torque, especially when starting under load.

Torque calculations must account for:

Conveyor length

Load weight

Incline or decline

Friction

Starting conditions

Starting torque is often significantly higher than running torque.

Service Factor and Duty Cycle

Conveyors rarely operate under perfectly smooth conditions.

Service factor must account for:

Shock loading

Frequent starts

Reversing operation

Continuous or near-continuous runtime

Underestimating service factor is one of the most common conveyor gearbox selection mistakes.

Overhung Load

Many conveyors apply overhung loads to the gearbox output shaft through belt drives, chain drives, or sprockets.

Overhung load creates bending forces that must be considered when selecting shaft size and bearing capacity.

Ignoring overhung load leads to bearing and shaft failures.

Mounting Orientation

Conveyor gearboxes are often mounted horizontally, vertically, or shaft-mounted.

Mounting orientation affects:

Lubrication distribution

Bearing loading

Seal performance

The gearbox must be approved for the intended mounting position.

Common Gearbox Types Used on Conveyors

Several gearbox designs are commonly used for conveyor applications.

Helical Gearboxes

Helical gearboxes are widely used due to their:

High efficiency

Smooth operation

Good load capacity

They are suitable for most conveyor applications, especially where efficiency and noise reduction are important.

Bevel and Helical-Bevel Gearboxes

Bevel and helical-bevel gearboxes are used when right-angle power transmission is required.

They offer good efficiency and are common in space-constrained conveyor layouts.

Shaft-Mounted Gearboxes

Shaft-mounted gearboxes are popular for belt and chain conveyors.

They eliminate couplings and reduce alignment requirements but must be properly sized for overhung load and torque.

Worm Gearboxes

Worm gearboxes are sometimes used for low-speed conveyors.

However, their lower efficiency and heat generation make them less suitable for continuous-duty or high-load conveyors.

Common Conveyor Gearbox Failures

Most conveyor gearbox failures follow predictable patterns.

Overloading and Undersizing

Undersized gearboxes are often selected based on running torque rather than starting torque.

Repeated overloads during startup cause gear tooth fatigue, bearing damage, and eventual failure.

Bearing Failures

Bearing failures are extremely common in conveyor gearboxes.

Causes include:

Excessive overhung load

Misalignment

Contamination

Insufficient lubrication

Bearing failure often leads to secondary gear and seal damage.

Seal Failures and Oil Leaks

Conveyor environments are often dusty, dirty, or wet.

Seal failures allow lubricant loss and contamination, accelerating internal wear.

Blocked breathers also cause pressure buildup that forces oil past seals.

Misalignment

Misalignment between motor, gearbox, and conveyor drive components creates uneven loading.

Misalignment leads to vibration, bearing wear, and shaft fatigue.

Lubrication Problems

Incorrect oil viscosity, contamination, or extended oil change intervals are major contributors to failure.

Conveyor gearboxes often operate continuously, making proper lubrication critical.

Thermal Overload

Heat buildup occurs when gearboxes are undersized, overloaded, or inefficient.

Thermal overload breaks down lubricant and reduces bearing life.

Early Warning Signs of Conveyor Gearbox Problems

Conveyor gearbox issues rarely appear without warning.

Common early indicators include:

Rising operating temperature

Increased noise or vibration

Oil leaks

Metal particles in oil

Increased motor current draw

Monitoring these signs helps prevent catastrophic failure.

Preventing Conveyor Gearbox Failures

Proper selection and maintenance significantly reduce failure risk.

Best practices include:

Accurate torque and speed calculations

Applying appropriate service factor

Accounting for overhung load

Selecting the correct gearbox type

Using proper lubrication

Maintaining seals and breathers

Performing routine inspections

Preventive maintenance is far less costly than unplanned downtime.

When to Upgrade or Replace a Conveyor Gearbox

A gearbox should be upgraded or replaced when:

Load requirements increase

Operating conditions change

Failure rates become frequent

Efficiency losses increase energy cost

Replacing an undersized gearbox with a properly selected unit often improves reliability immediately.

Final Thoughts

Conveyors place demanding requirements on gearboxes, making correct selection critical.

Most conveyor gearbox failures are caused by undersizing, improper service factor, overhung load, or poor lubrication.

Understanding conveyor-specific requirements and common failure modes helps extend gearbox life and reduce downtime.

If you need help selecting or troubleshooting a gearbox for a conveyor application, IndustrialGearboxSupply.com can help guide you toward the right solution.