Gear Reducer Ratio vs Output Speed Explained

Gear reducer ratio and output speed are directly connected, yet they are often misunderstood. Selecting the wrong ratio can result in improper machine speed, reduced torque, overheating, or premature failure.

This article explains how gear reducer ratio affects output speed, how to calculate it, and how to choose the correct ratio for your application.

What Is a Gear Reducer Ratio?

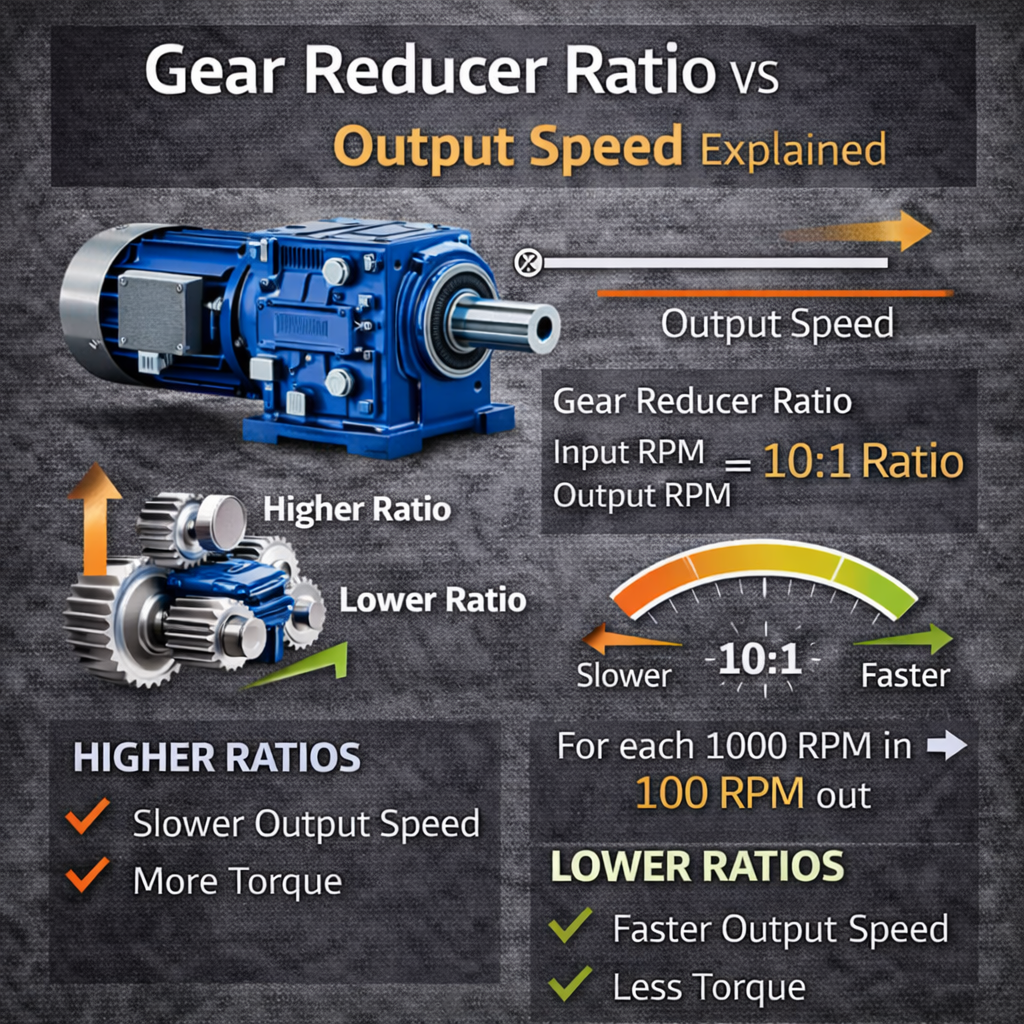

The gear reducer ratio describes how much the input speed is reduced before reaching the output shaft.

It is typically expressed as:

Ratio = Input Speed ÷ Output Speed

Or written as X:1, meaning the input shaft rotates X times for one output shaft rotation

For example:

A 10:1 ratio means the input shaft turns 10 times for every 1 output shaft rotation.

Higher ratios result in lower output speed and higher torque.

What Is Output Speed?

Output speed is the rotational speed of the gearbox output shaft, usually measured in RPM (revolutions per minute).

Output speed determines:

Conveyor belt speed

Mixer rotation speed

Fan or pump operating speed

Machine cycle time

Choosing the correct output speed is critical for proper equipment operation.

How Gear Reducer Ratio Affects Output Speed

Gear reducer ratio directly controls output speed.

The relationship is simple:

Higher ratio = Lower output speed

Lower ratio = Higher output speed

Basic Formula

Output Speed (RPM) = Input Speed (RPM) ÷ Gear Ratio

Example:

Motor speed: 1,800 RPM

Gear ratio: 20:1

Output speed: 1,800 ÷ 20 = 90 RPM

This relationship applies to all gearbox types, including inline, right-angle, helical, planetary, and worm gear reducers.

Common Gear Reducer Ratios and Output Speeds

Using a standard 1,800 RPM motor:

5:1 ratio → 360 RPM output

10:1 ratio → 180 RPM output

20:1 ratio → 90 RPM output

30:1 ratio → 60 RPM output

60:1 ratio → 30 RPM output

Higher ratios reduce speed more aggressively but increase torque.

Ratio vs Torque Trade-Off

Reducing speed increases torque.

As ratio increases:

Output speed decreases

Output torque increases

Efficiency may decrease slightly depending on gearbox type

This trade-off is essential to understand when sizing a gear reducer.

Single-Stage vs Multi-Stage Gear Reducers

Single-Stage Gear Reducers

Single-stage reducers:

Provide lower ratios

Offer high efficiency

Are compact and simple

Typical ratios:

Up to 10:1 or 15:1 depending on design

Multi-Stage Gear Reducers

Multi-stage reducers:

Combine multiple gear stages

Achieve higher ratios

Maintain manageable gear sizes

Typical ratios:

20:1 to 100:1 or more

Higher ratios often require multiple stages to maintain efficiency and durability.

Effect of Gearbox Type on Ratio and Speed

Different gearbox designs handle ratios differently.

Helical Gear Reducers

Helical reducers:

Handle moderate to high ratios efficiently

Maintain high efficiency

Are ideal for continuous-duty applications

Worm Gear Reducers

Worm reducers:

Offer very high ratios in compact designs

Have lower efficiency at higher ratios

Are commonly used for low-speed applications

Planetary Gear Reducers

Planetary reducers:

Offer high ratios with compact size

Provide high torque density

Maintain good efficiency

Are often used in precision applications

Gearbox type influences efficiency and heat at higher ratios.

Real-World Considerations Beyond the Formula

While the math is simple, real-world applications require additional consideration.

Motor Speed Variations

Motor speed may vary due to:

VFD operation

Load changes

Slip in induction motors

These factors affect actual output speed.

Load and Efficiency Losses

Efficiency losses slightly reduce output speed under load.

Lower efficiency gearboxes may produce less usable output power at high ratios.

Service Factor and Duty Cycle

Operating near maximum torque continuously can reduce gearbox life, even if speed calculations are correct.

Proper service factor selection is critical.

Common Mistakes When Selecting Gear Reducer Ratio

Common errors include:

Selecting ratio based only on speed, not torque

Ignoring startup and peak loads

Overlooking efficiency losses

Failing to account for VFD speed range

Choosing too high a ratio when motor speed could be adjusted instead

These mistakes often lead to overheating or premature failure.

How to Choose the Correct Gear Reducer Ratio

To select the correct ratio:

Determine required output speed

Identify motor speed

Calculate required ratio

Confirm torque requirements

Evaluate gearbox type and efficiency

Check service factor and duty cycle

Confirm mounting and space constraints

Proper selection ensures reliable operation and long service life.

Final Thoughts

Gear reducer ratio and output speed are tightly linked, and understanding their relationship is essential for selecting the right gearbox.

While the calculation is straightforward, proper application requires considering torque, efficiency, gearbox type, and operating conditions.

Choosing the correct ratio improves performance, reduces downtime, and extends gearbox life.

If you need help selecting the correct gear reducer ratio for your application, IndustrialGearboxSupply.com can help evaluate your requirements and recommend the right solution.