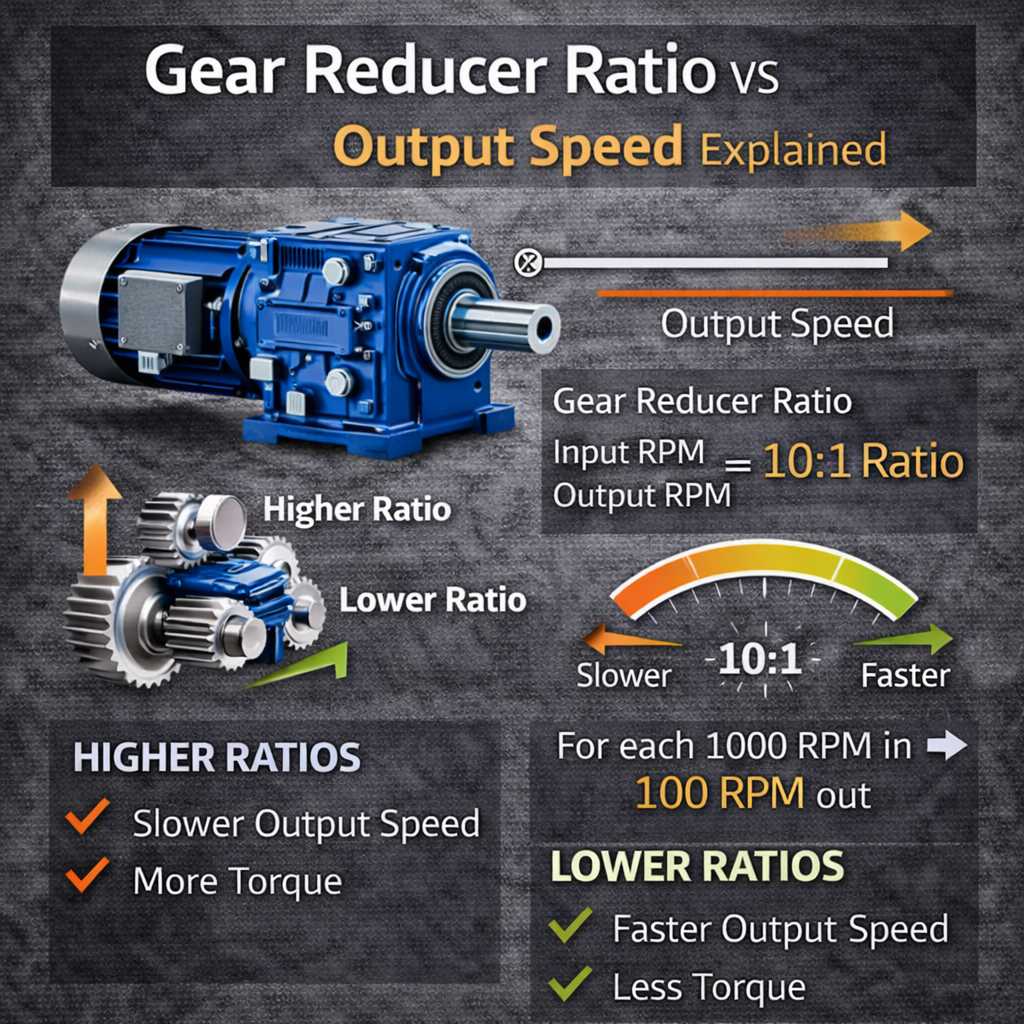

Gear Reducer Ratio vs Output Speed Explained

Gear reducer ratio directly controls output speed and torque. This guide explains how ratios work, how to calculate output speed, and how to select the right ratio.

Foot-Mounted vs Flange-Mounted Gearboxes

Foot-mounted and flange-mounted gearboxes differ in load support, alignment, and maintenance. This guide explains the pros and cons of each mounting style.

Planetary vs Helical Gearboxes: Precision vs Durability

Planetary and helical gearboxes serve different purposes. This article compares precision, durability, and application strengths to help you choose the right gearbox design.

Inline vs Right-Angle Gearboxes: Pros & Cons

Inline and right-angle gearboxes differ in efficiency, layout, and maintenance. This article compares the pros and cons to help you choose the right gearbox design.

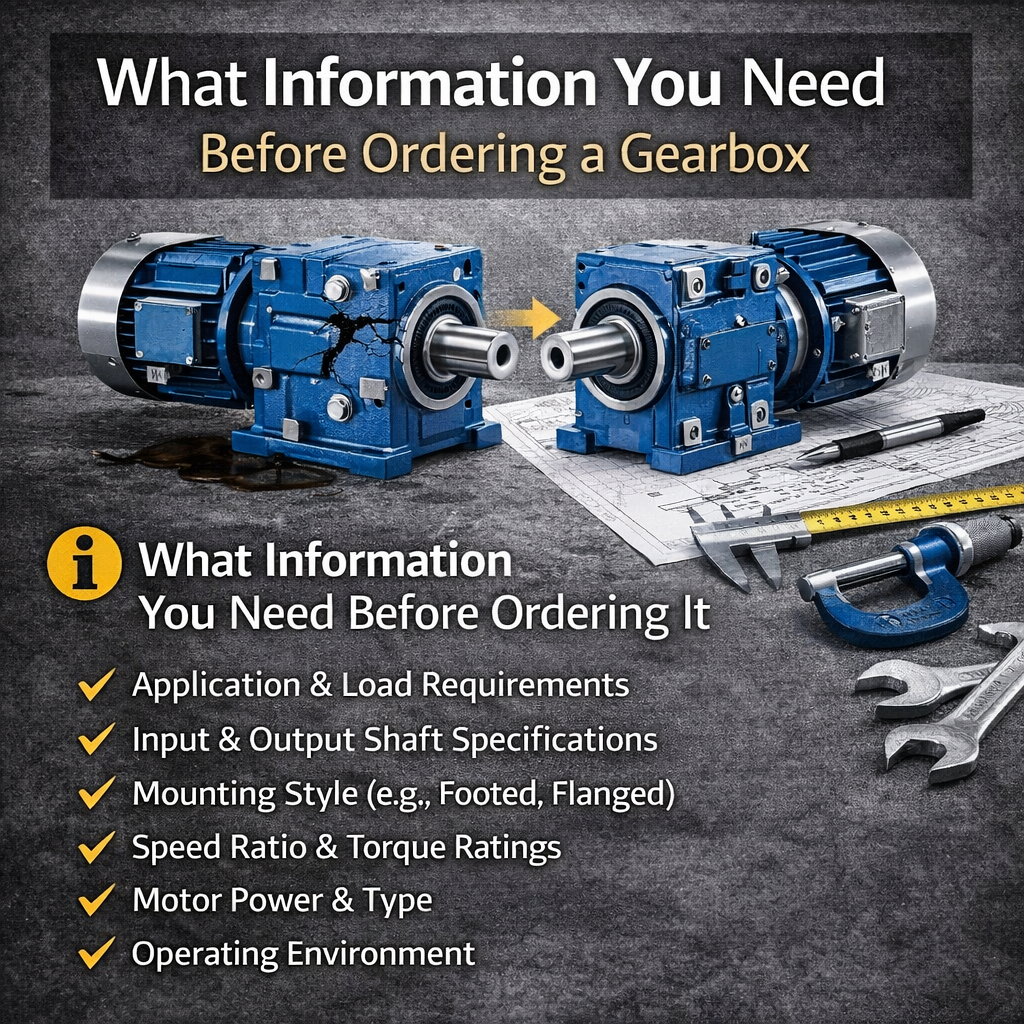

Common Gearbox Ordering Mistakes

Many gearbox failures start before installation due to ordering mistakes. This article explains the most common gearbox ordering errors and how to avoid them.

What Information You Need Before Ordering a Gearbox

Ordering a gearbox without complete information often leads to delays, incorrect sizing, and premature failure. This article outlines exactly what you need before placing an order.

Gearboxes for Variable Speed Applications

Variable speed applications expose gearboxes to changing torque, speed, and thermal conditions. This article explains how to select gearboxes designed for reliable variable speed operation.

Gearboxes for Heavy Shock Loads

Heavy shock loads create sudden torque spikes that damage gears and bearings. This article explains how to select gearboxes designed to withstand impact and prevent failure.

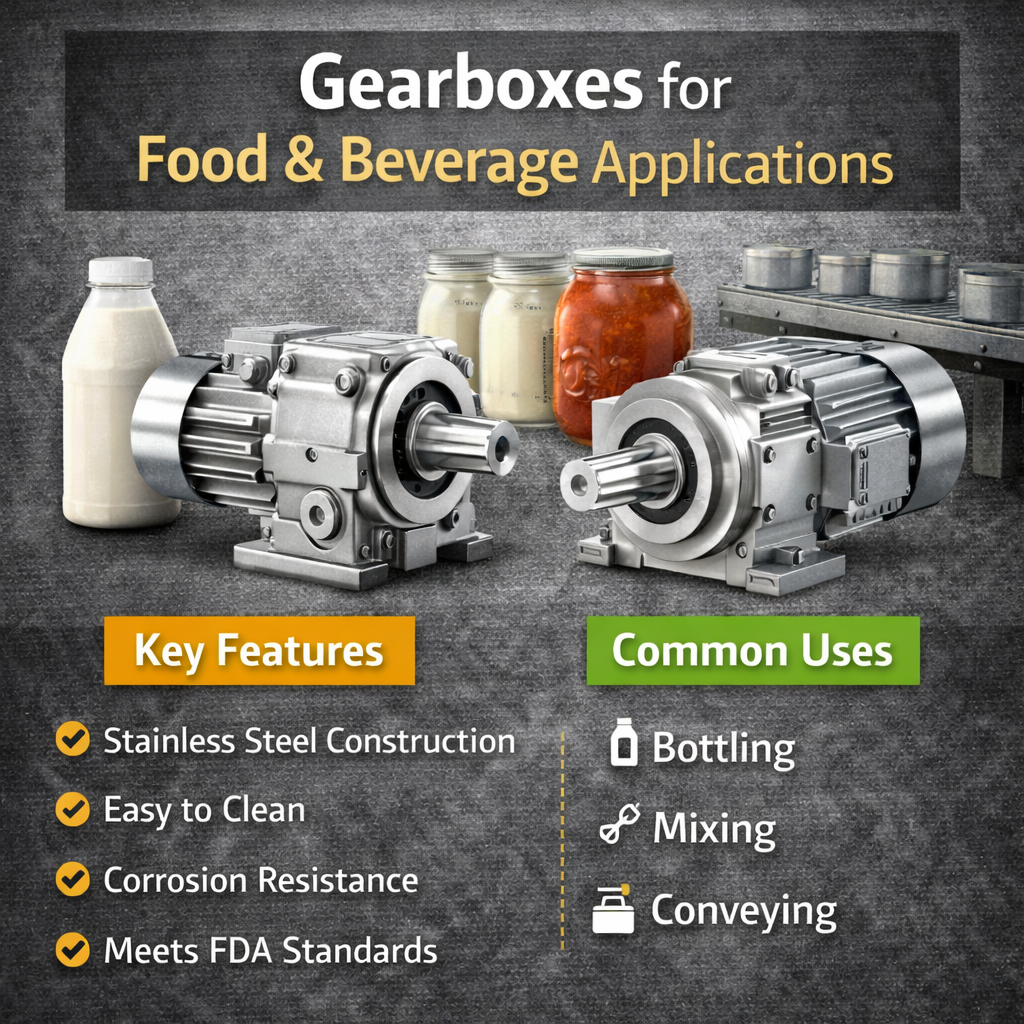

Gearboxes for Food & Beverage Applications

Food and beverage applications require gearboxes that meet strict sanitation standards while delivering reliable performance. This article explains how to select food-grade gearboxes and avoid common failures.

Gearboxes for Packaging Equipment

Packaging equipment requires gearboxes that balance speed, precision, and reliability. This article explains how to select the right gearbox and prevent common failures in packaging applications.

Gearboxes for Mixers and Agitators

Mixers and agitators place heavy, variable loads on gearboxes. This article explains how to select the right gearbox and prevent common failures in mixing applications.

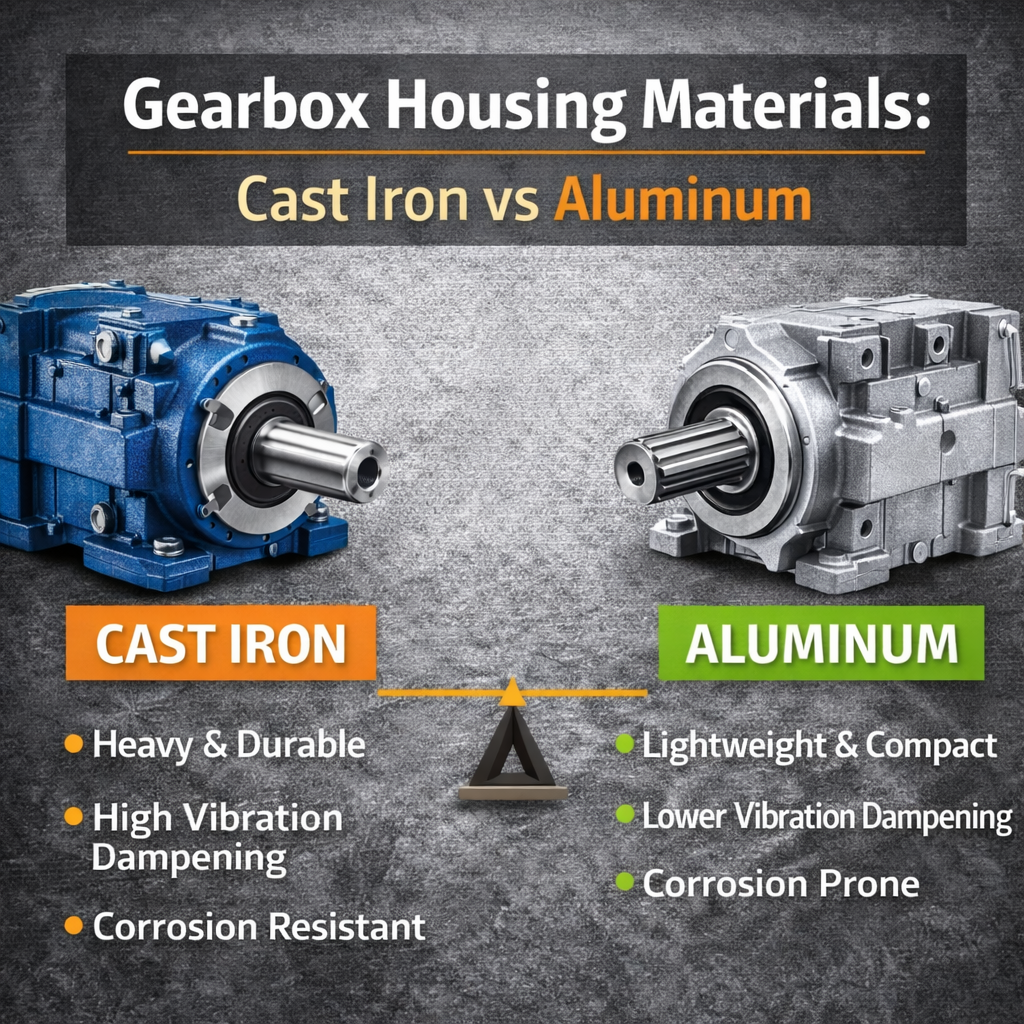

Gearbox Housing Materials: Cast Iron vs Aluminum

Gearbox housing material affects strength, vibration control, and durability. This article compares cast iron vs aluminum gearbox housings and explains when each is the better choice.

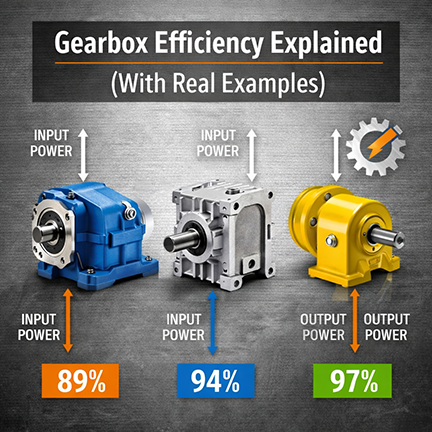

Gearbox Efficiency Explained (With Real Examples)

Gearbox efficiency determines how much input power reaches the output shaft. This article explains gearbox efficiency, where losses occur, and includes real-world examples comparing gearbox types.

Gearbox Speed Reduction Formula Explained

Gearbox speed reduction determines output RPM and torque. This article explains the gearbox speed reduction formula, how to calculate output speed, and how proper ratio selection affects performance and reliability.

How to Calculate Gearbox Torque (Step-by-Step)

Calculating gearbox torque correctly is critical for proper gearbox selection and long-term reliability. This step-by-step guide explains how to calculate input and output torque using horsepower, RPM, efficiency, and service factor.

Helical vs Worm vs Planetary Gearboxes: Which One Is Right for You?

Learn the difference between helical, worm, and planetary gearboxes and how to choose the best one for your industrial application. Includes a feature comparison table and free tool recommendations.

Industrial Gearbox Types: Choosing the Right Gearbox for Your Application

From helical to planetary, choosing the right gearbox type depends on torque, layout, speed, and application. Explore all major gearbox types in this complete guide.