Gearbox Alignment: Why It Matters and How to Do It Right

What Is Gearbox Alignment?

Gearbox alignment is the precise positioning of a gearbox’s input and output shafts with the connected motor or driven equipment. Even minor misalignments can cause premature bearing wear, seal leaks, gear damage, and increased vibration, ultimately leading to gearbox failure.

Why Proper Alignment Is Crucial

Failing to align a gearbox correctly can result in:

⚠️ Excessive wear on bearings, seals, and gears

🔊 Increased vibration and noise during operation

💸 Reduced energy efficiency and output

🛠️ Frequent maintenance needs or unplanned downtime

A properly aligned gearbox runs cooler, lasts longer, and maintains peak performance.

Types of Misalignment

There are three main types of gearbox misalignment:

| Type | Description | Example |

|---|---|---|

| Angular Misalignment | Shafts are at an angle to each other | Output shaft is tilted vs. driven shaft |

| Parallel (Offset) Misalignment | Shafts are parallel but not collinear | Horizontal or vertical offset |

| Combination Misalignment | Angular and offset exist together | Most common in industrial setups |

Common Symptoms of Gearbox Misalignment

Unusual vibration or resonance

Loud gear or bearing noise

Coupling failure or unusual coupling wear

Excessive heat near seals or bearings

Premature bearing or seal leakage

If you notice any of these, alignment should be checked immediately.

How to Check and Correct Gearbox Alignment

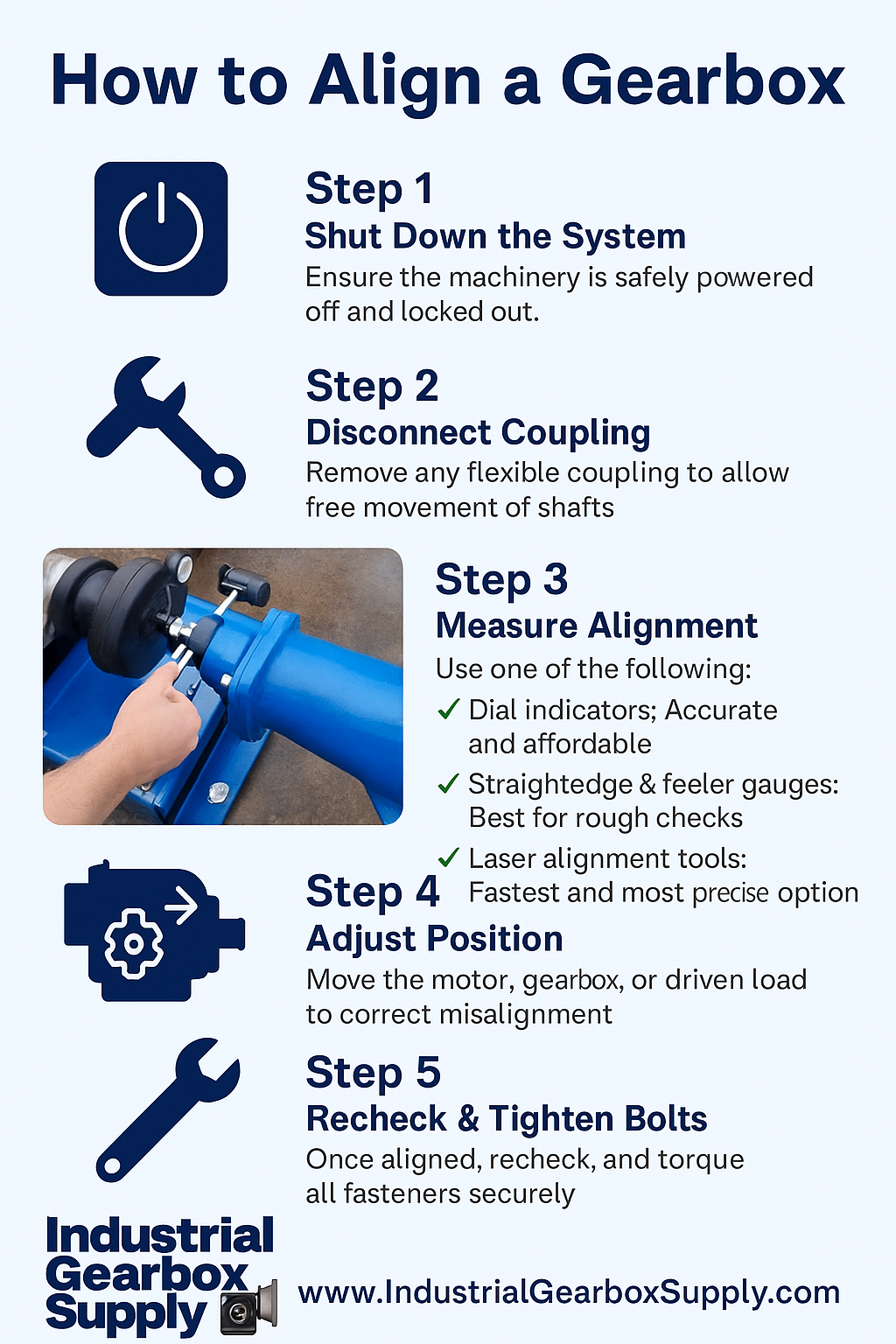

Step 1: Shut Down the System

Ensure the machinery is safely powered off and locked out.

Step 2: Disconnect Coupling

Remove any flexible coupling to allow free movement of shafts.

Step 3: Measure Alignment

✅ Use one of the following:

Dial indicators: Accurate and affordable

Straightedge & feeler gauges: Best for rough checks

Laser alignment tools: Fastest and most precise option

Step 4: Adjust Position

Move the motor, gearbox, or driven load to correct misalignment.

Step 5: Recheck & Tighten Bolts

Once aligned, recheck, and torque all fasteners securely.

Laser Alignment vs. Manual Methods

| Feature | Laser Alignment | Manual Alignment |

|---|---|---|

| Speed | Fast | Time-consuming |

| Accuracy | High (within .001") | Moderate |

| Cost | Higher upfront | Low cost tools |

| Ease of Use | User-friendly interface | Requires skilled operator |

Best Practices for Long-Term Alignment Success

🛠️ Recheck alignment after system runs for a few hours

📅 Include alignment checks in your preventive maintenance plan

🔄 Always realign after moving or servicing connected machinery

⚖️ Ensure foundations and bases are level and vibration-free

Gearbox Alignment Services Available

At Industrial Gearbox Supply, we offer:

✅ Laser gearbox alignment services

✅ On-site inspections and emergency support

✅ Coupling replacements and vibration diagnostics

✅ Fast delivery on replacement gearboxes if failure has occurred

📍 Location: 3590 Scheele Dr, Jackson, MI 49202

📧 Email: sales@industrialgearboxsupply.com

📞 Phone: (517) 858-2966

🌐 Website: www.IndustrialGearboxSupply.com

Final Thoughts

Proper gearbox alignment is more than a maintenance task—it’s a critical investment in your equipment’s reliability. Misalignment leads to costly repairs, but a few careful checks can prevent thousands in downtime.

Need help aligning your gearbox or replacing a damaged unit?

Contact Industrial Gearbox Supply today for expert service and fast turnaround.

Frequently Asked Questions

What is gearbox alignment?

Gearbox alignment is the precise positioning of a gearbox’s input and output shafts with connected components to reduce vibration, wear, and energy loss.

What are signs of gearbox misalignment?

Look for symptoms like excessive vibration, seal or bearing leaks, loud noises, or unusual coupling wear.

How do I align a gearbox?

Shut down the machine, remove the coupling, use tools like dial indicators or laser alignment systems, and adjust the position until proper alignment is achieved. Then recheck and torque all fasteners.

Is laser alignment better than manual methods?

Laser alignment is more accurate and quicker, though more expensive. Manual alignment is more affordable but requires precision and skill.