Gearbox Bearings: Types, Functions, and Failure Modes

Gearbox bearings are critical components that support shafts, maintain alignment, and allow smooth transmission of power. While gears often receive the most attention, bearing failure is one of the most common causes of gearbox breakdowns.

Understanding gearbox bearing types, their functions, and common failure modes helps prevent unexpected downtime and extends gearbox service life.

What Bearings Do Inside a Gearbox

Bearings support rotating shafts while minimizing friction and controlling movement. Inside a gearbox, bearings must handle combinations of radial loads, axial loads, and dynamic forces created by gear meshing.

Proper bearing performance ensures:

Accurate gear alignment

Smooth torque transmission

Low vibration and noise

Controlled shaft positioning

When bearings fail, secondary damage to gears, seals, and housings often follows.

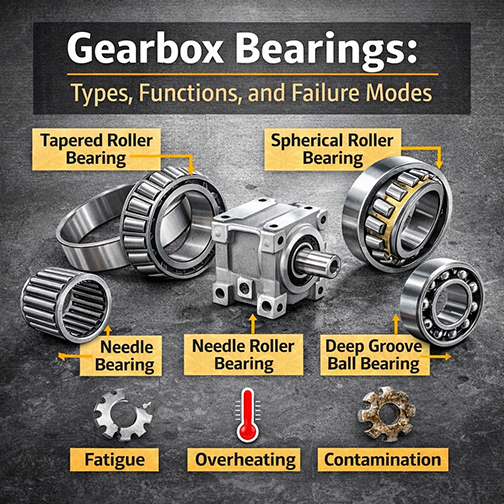

Common Types of Gearbox Bearings

Industrial gearboxes use several bearing types depending on load, speed, and design requirements.

Ball Bearings

Ball bearings are commonly used in light to moderate load applications.

They are well suited for:

High-speed operation

Low to moderate radial and axial loads

Compact gearbox designs

Ball bearings offer low friction but have limited load-carrying capacity compared to roller bearings.

Cylindrical Roller Bearings

Cylindrical roller bearings handle higher radial loads than ball bearings.

They are commonly used in:

Helical gearboxes

High-torque applications

Gearboxes with heavy radial loading

These bearings allow high load capacity but typically require separate axial load control.

Tapered Roller Bearings

Tapered roller bearings are designed to handle combined radial and axial loads.

They are frequently used in:

Bevel gearboxes

Right-angle gearboxes

Applications requiring precise shaft positioning

Proper preload adjustment is critical for tapered roller bearings to avoid overheating or premature wear.

Spherical Roller Bearings

Spherical roller bearings accommodate misalignment and heavy loads.

They are often found in:

Large industrial gearboxes

Shock-load applications

Equipment subject to shaft deflection

Their self-aligning capability makes them suitable for demanding environments.

Thrust Bearings

Thrust bearings support axial loads only.

They are used when:

Significant axial forces are present

Gear geometry creates thrust loads

Shaft positioning must be controlled

Thrust bearings are often paired with other bearing types to handle combined loads.

How Bearings Affect Gearbox Performance

Bearing selection directly impacts gearbox efficiency, noise, and lifespan.

Incorrect bearing type or size can lead to:

Excessive friction

Increased heat generation

Shaft misalignment

Gear tooth damage

Bearings also influence lubrication flow and thermal behavior inside the gearbox.

Common Gearbox Bearing Failure Modes

Most gearbox bearing failures follow predictable patterns.

Lubrication Failure

Insufficient, incorrect, or contaminated lubrication is the leading cause of bearing failure.

Lubrication problems lead to:

Metal-to-metal contact

Excessive heat

Rapid surface wear

Incorrect oil viscosity or degraded lubricant accelerates bearing damage.

Contamination

Dirt, moisture, and debris entering the gearbox damage bearing surfaces.

Contamination causes:

Abrasive wear

Surface pitting

Accelerated fatigue

Even small particles can significantly reduce bearing life.

Overloading

Bearings designed for specific load ratings fail prematurely when overloaded.

Overloading may result from:

Incorrect gearbox sizing

Excessive torque

Shock loads

Improper service factor selection

Overloaded bearings often show spalling or cage damage.

Misalignment

Shaft misalignment places uneven loads on bearing elements.

Misalignment causes:

Edge loading

Increased vibration

Premature fatigue

Misalignment often originates from improper mounting or foundation issues.

Improper Installation

Incorrect installation practices frequently damage bearings before operation even begins.

Common installation errors include:

Hammering bearings onto shafts

Incorrect preload or clearance

Improper heating methods

Misaligned bearing seats

Installation damage often leads to early failure.

Fatigue and Wear

Even properly maintained bearings eventually fail due to fatigue.

Rolling contact fatigue appears as:

Surface spalling

Flaking

Pitting

Bearing life depends on load, speed, lubrication, and operating conditions.

Early Warning Signs of Bearing Failure

Bearing problems usually develop gradually.

Common warning signs include:

Increasing vibration

Unusual noise (whining or grinding)

Rising operating temperature

Metal particles in oil

Increased power consumption

Early detection allows corrective action before catastrophic failure.

How Bearing Failure Impacts the Entire Gearbox

Bearing failure rarely occurs in isolation.

Failed bearings often lead to:

Gear tooth misalignment

Seal damage and leakage

Housing wear

Secondary gear failure

Addressing bearing issues early prevents expensive cascading damage.

Preventing Gearbox Bearing Failure

Preventive measures include:

Correct bearing selection

Proper lubrication type and viscosity

Clean oil and contamination control

Accurate alignment and mounting

Routine vibration and oil analysis

Following manufacturer installation procedures

Preventive maintenance significantly extends bearing and gearbox life.

When Bearings Should Be Replaced

Bearings should be replaced when:

Vibration or noise trends worsen

Spalling or pitting is detected

Oil analysis indicates wear debris

Gearbox is disassembled for major service

Proactive bearing replacement is often more cost-effective than reactive repairs.

Final Thoughts

Gearbox bearings play a critical role in supporting loads, maintaining alignment, and ensuring smooth operation. Understanding bearing types, functions, and failure modes helps prevent unexpected breakdowns and extends gearbox life.

Most gearbox failures can be traced back to bearing issues caused by lubrication problems, contamination, misalignment, or overload.

If you need help diagnosing bearing-related gearbox issues or selecting the correct bearing solution, IndustrialGearboxSupply.com can help guide you toward the right answer.