Gearbox Efficiency Explained (With Real Examples)

Gearbox efficiency plays a major role in energy consumption, heat generation, and long-term reliability. While efficiency is often overlooked during gearbox selection, small efficiency losses can translate into significant energy waste, higher operating temperatures, and premature wear over time.

This article explains what gearbox efficiency is, what affects it, how different gearbox types compare, and includes real-world examples to show how efficiency impacts performance.

What Is Gearbox Efficiency?

Gearbox efficiency is a measure of how much input power is converted into usable output power.

It is expressed as a percentage:

Efficiency (%) = (Output Power ÷ Input Power) × 100

An efficiency of 95% means that 95% of the input power reaches the output shaft, while 5% is lost to friction, heat, and internal resistance.

Why Gearbox Efficiency Matters

Efficiency directly affects:

Energy consumption

Heat generation

Lubricant life

Bearing and gear wear

Overall operating cost

Lower efficiency means more energy is converted into heat instead of useful work. Excess heat accelerates lubricant breakdown and increases internal wear.

Over time, efficiency losses shorten gearbox life and increase maintenance costs.

Where Efficiency Loss Comes From

Efficiency losses inside a gearbox come from several sources.

Gear tooth sliding friction, bearing friction, seal drag, lubricant churning, and windage all contribute to power loss.

The more contact surfaces and sliding motion inside the gearbox, the greater the efficiency loss.

Typical Efficiency by Gearbox Type

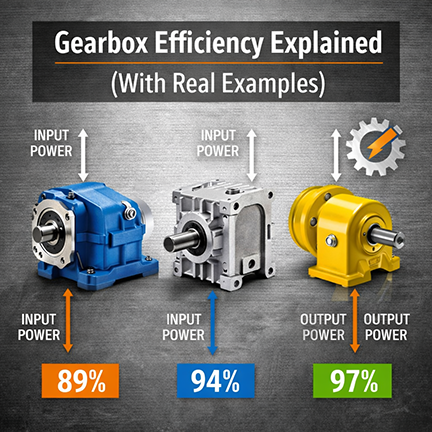

Different gearbox designs have inherently different efficiency levels.

Helical gearboxes typically operate at 94–98% efficiency per stage due to rolling contact and minimal sliding.

Bevel gearboxes have similar efficiency ranges, usually 93–97%, depending on load and geometry.

Planetary gearboxes are highly efficient, often 95–98%, and maintain efficiency even at higher torque levels due to load sharing across multiple gears.

Worm gearboxes have the widest efficiency range. Depending on ratio, design, and lubrication, efficiency may range from 50% to 90%. High-ratio worm gearboxes generally have lower efficiency due to increased sliding friction.

Real Example: Helical Gearbox Efficiency

A conveyor is driven by a 10 HP motor using a helical gearbox with 96% efficiency.

Input power = 10 HP

Output power = 10 × 0.96 = 9.6 HP

Only 0.4 HP is lost as heat.

This gearbox runs relatively cool and maintains lubricant life over long duty cycles.

Real Example: Worm Gearbox Efficiency

The same conveyor uses a worm gearbox with 70% efficiency.

Input power = 10 HP

Output power = 10 × 0.70 = 7.0 HP

3 HP is lost as heat.

This additional heat significantly raises operating temperature, reduces lubricant life, and increases energy cost.

In continuous-duty applications, this efficiency loss can justify switching gearbox types.

Efficiency vs Torque and Ratio

Efficiency is not constant—it changes with ratio and load.

Higher ratios generally reduce efficiency, especially in worm gearboxes. Light loads can also reduce efficiency because friction losses become a larger percentage of total power.

Operating a gearbox near its optimal load range improves efficiency and reduces heat.

How Lubrication Affects Efficiency

Lubricant selection has a direct impact on efficiency.

Incorrect viscosity increases churning losses and drag. Contaminated or degraded oil increases friction and heat generation.

High-quality synthetic lubricants often improve efficiency slightly while significantly improving temperature control and lubricant life.

Efficiency Loss Over Time

Gearbox efficiency declines over time if maintenance is neglected.

Contamination, wear debris, seal drag, misalignment, and lubricant degradation all reduce efficiency gradually.

Rising temperature is often the first sign of declining efficiency.

Measuring Gearbox Efficiency in the Field

Direct efficiency measurement is difficult, but indirect indicators include:

Rising operating temperature

Increased energy consumption

Higher motor current draw

Reduced output performance

Comparing baseline operating data to current conditions helps identify efficiency loss.

Choosing a Gearbox With Efficiency in Mind

Efficiency should be considered alongside torque, ratio, and service factor.

For continuous-duty or energy-sensitive applications, higher-efficiency gearbox designs often provide lower total cost of ownership despite higher upfront cost.

In intermittent or low-duty applications, efficiency may be less critical.

When Efficiency Loss Signals a Problem

Sudden drops in efficiency often indicate mechanical issues such as:

Misalignment

Bearing damage

Lubrication failure

Contamination

Efficiency loss should never be ignored, as it often precedes more serious failures.

Final Thoughts

Gearbox efficiency has a direct impact on performance, heat, energy cost, and service life. Understanding how efficiency works and how it varies by gearbox type helps you make better selection and maintenance decisions.

Real-world examples show that efficiency losses are not just theoretical—they have measurable cost and reliability consequences.

If you need help selecting an efficient gearbox or evaluating efficiency-related issues in your application, IndustrialGearboxSupply.com can help guide you toward the right solution.