Gearbox Seals Explained: Types, Materials, and Wear Signs

Gearbox seals play a critical role in retaining lubricant and preventing contamination. While seals are relatively small components, seal failure is a leading cause of oil leaks, contamination, bearing damage, and premature gearbox failure.

Understanding gearbox seal types, materials, and early wear signs helps prevent costly downtime and secondary damage.

What Gearbox Seals Do

Gearbox seals serve two primary functions:

They keep lubricant inside the gearbox and keep contaminants out.

By maintaining a sealed environment, gearbox seals protect gears, bearings, and internal components from dirt, moisture, and debris while ensuring proper lubrication.

When seals fail, lubricant loss and contamination quickly degrade gearbox performance.

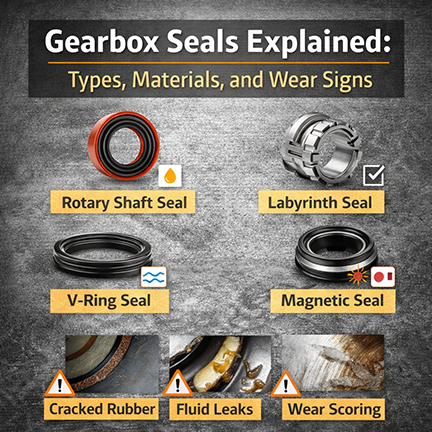

Common Types of Gearbox Seals

Industrial gearboxes use several seal types depending on shaft speed, pressure, temperature, and environment.

Radial Lip Seals

Radial lip seals are the most common gearbox seal type.

They consist of a flexible sealing lip that contacts the rotating shaft, usually assisted by a garter spring to maintain pressure.

Radial lip seals are effective for:

Moderate shaft speeds

Oil retention

Standard industrial environments

They are widely used on both input and output shafts.

Mechanical Seals

Mechanical seals use two flat sealing faces—one rotating and one stationary—to create a tight seal.

They are used in more demanding applications where leakage must be minimized.

Mechanical seals are suitable for:

High shaft speeds

Higher pressures

Severe operating conditions

They are less common in standard gearboxes but may be used in specialized designs.

Labyrinth Seals

Labyrinth seals do not rely on direct contact with the shaft.

Instead, they use a series of grooves or passages that restrict contaminant entry while allowing minimal leakage.

Labyrinth seals are ideal for:

High-speed applications

Dusty environments

Situations where minimal friction is desired

They are often paired with other seal types for added protection.

V-Ring Seals

V-ring seals are elastomeric seals that rotate with the shaft and seal axially against a stationary surface.

They provide secondary sealing and are often used to protect primary seals from contamination.

V-rings are especially effective in dirty or wet environments.

Common Gearbox Seal Materials

Seal material selection depends on temperature, lubricant type, chemical exposure, and operating conditions.

Nitrile Rubber (NBR)

Nitrile rubber is the most common seal material.

It offers good resistance to:

Mineral oils

Moderate temperatures

General industrial conditions

NBR seals are cost-effective but have limited high-temperature capability.

Fluoroelastomer (FKM / Viton®)

FKM seals provide superior resistance to:

High temperatures

Synthetic oils

Chemical exposure

They are commonly used in high-temperature or continuous-duty applications.

Polyacrylate (ACM)

Polyacrylate seals are used where higher temperature resistance is needed than NBR but chemical exposure is moderate.

They are often found in automotive and light industrial applications.

Polytetrafluoroethylene (PTFE)

PTFE seals offer excellent chemical resistance and low friction.

They perform well in:

High-speed applications

Harsh chemical environments

Extreme temperatures

PTFE seals are more expensive and often require precise installation.

How Shaft Surface Finish Affects Seal Life

Seal performance depends heavily on shaft surface finish.

Rough, damaged, or improperly machined shafts accelerate seal wear and cause leaks.

Shafts should meet manufacturer-recommended surface finish and hardness specifications to ensure long seal life.

Common Wear Signs of Gearbox Seal Failure

Seal failure usually develops gradually.

Oil Leaks

Visible oil leakage around the shaft is the most obvious sign of seal failure.

Leaks may appear as:

Oil dripping

Oil misting

Grease buildup mixed with dirt

Even minor leaks should be addressed promptly.

Contamination Inside the Gearbox

Seal failure allows dirt, dust, and moisture to enter the gearbox.

Contamination leads to:

Abrasive wear

Bearing damage

Lubricant degradation

Water contamination is especially damaging and often results from failed seals.

Hardened or Cracked Seals

Heat and age cause elastomer seals to harden and crack.

Hardened seals lose flexibility and sealing pressure, leading to leakage.

Grooved or Worn Shafts

Seals running on damaged shafts wear rapidly.

Grooves, corrosion, or fretting on the shaft surface indicate prolonged seal issues.

Increased Temperature and Noise

Lubricant loss from leaking seals increases friction and heat.

Rising temperature and unusual noise often follow seal failure.

Common Causes of Gearbox Seal Failure

Several factors contribute to premature seal failure.

Improper installation is a major cause. Installing seals crooked, damaged, or without proper lubrication shortens seal life.

Misalignment between shafts and bearings causes uneven seal contact and rapid wear.

Excessive pressure inside the gearbox, often caused by blocked breathers, forces lubricant past seals.

Incorrect seal material selection leads to chemical or thermal degradation.

Contamination during installation damages sealing surfaces from the start.

Preventing Gearbox Seal Failure

Seal life can be significantly extended with proper practices.

Ensure correct seal material selection based on temperature, lubricant, and environment.

Maintain proper shaft finish and alignment.

Keep breathers clean to prevent pressure buildup.

Replace seals during major gearbox service rather than waiting for visible leaks.

Use protective measures such as V-rings or labyrinth seals in harsh environments.

When to Replace Gearbox Seals

Gearbox seals should be replaced when:

Leakage is observed

Gearbox is opened for service

Seal material shows aging or hardening

Shaft wear is detected

Contamination is present in the lubricant

Proactive seal replacement is far less costly than repairing contamination-related damage.

Final Thoughts

Gearbox seals may be small components, but they play a vital role in gearbox reliability. Understanding seal types, materials, and early wear signs helps prevent lubricant loss, contamination, and secondary failures.

Most gearbox bearing and gear failures begin with seal problems that go unaddressed.

If you need help selecting the correct gearbox seal or diagnosing seal-related issues, IndustrialGearboxSupply.com can help guide you toward the right solution.