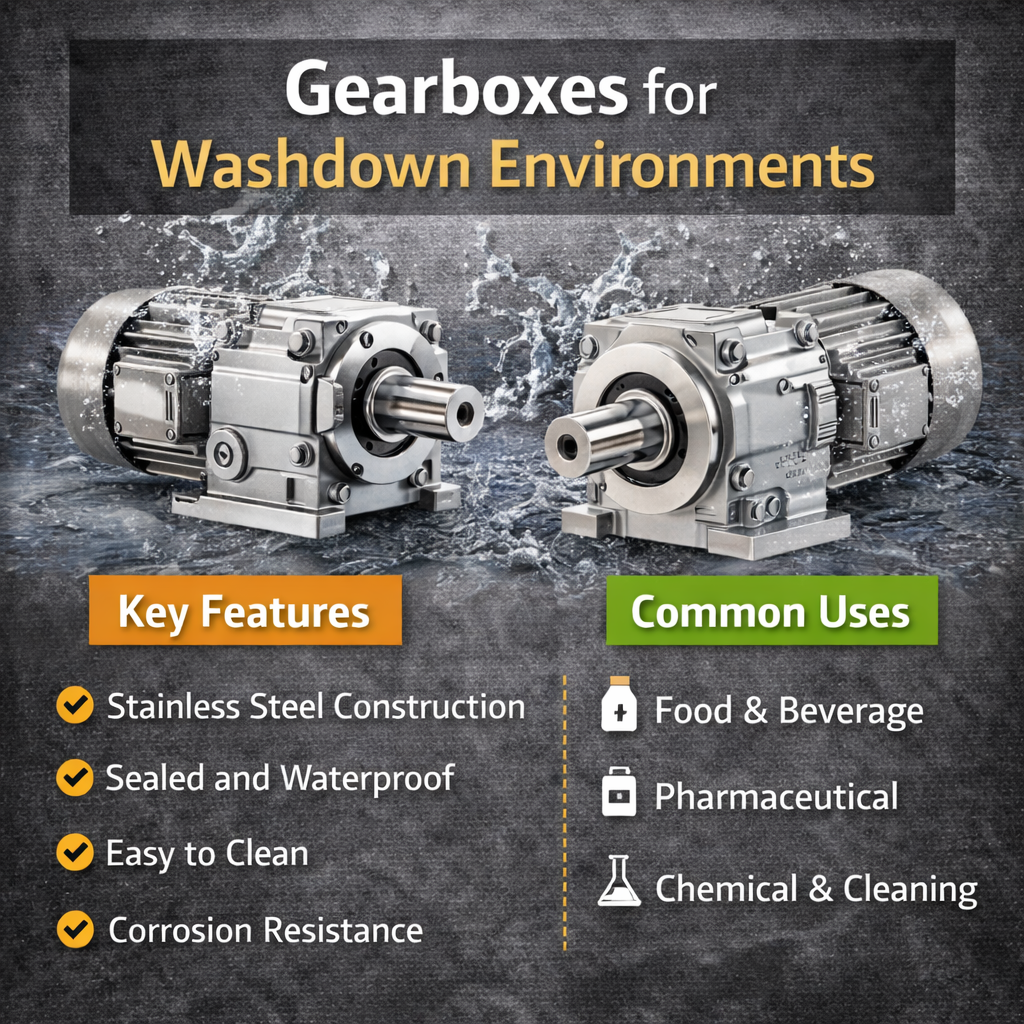

Gearboxes for Washdown Environments

Washdown environments are among the most challenging operating conditions for industrial gearboxes. Frequent exposure to water, chemicals, and high-pressure cleaning systems dramatically increases the risk of corrosion, seal failure, lubricant contamination, and premature gearbox failure.

This article explains how to properly select gearboxes for washdown environments and outlines the most common failure modes seen in these demanding applications.

What Is a Washdown Environment?

A washdown environment is any industrial setting where equipment is regularly cleaned using water, steam, or chemical solutions. These cleanings may involve high pressure, elevated temperatures, or aggressive sanitizing agents.

Common washdown environments include:

Food and beverage processing

Dairy and meat processing facilities

Pharmaceutical manufacturing

Breweries and bottling plants

Chemical processing areas

Sanitary packaging operations

Gearboxes in these environments must withstand repeated exposure without compromising performance or hygiene.

Why Standard Gearboxes Fail in Washdown Applications

Many standard industrial gearboxes are not designed for washdown conditions.

Common vulnerabilities include:

Porous or rough housing surfaces

Unsealed fasteners

Standard shaft seals not rated for high-pressure water

Inadequate corrosion protection

Improper breathers allowing moisture ingress

When exposed to washdown conditions, these weaknesses quickly lead to failure.

Key Gearbox Selection Factors for Washdown Environments

Selecting the correct gearbox requires attention to both mechanical performance and environmental protection.

Housing Material and Finish

Housing material is critical in washdown environments.

Common options include:

Stainless steel housings for aggressive or frequent washdowns

Aluminum housings with protective coatings for moderate washdown

Epoxy-coated or nickel-plated cast iron housings in limited washdown areas

Smooth, non-porous surfaces reduce bacteria buildup and make cleaning easier.

Sealing Systems

Seals are one of the most failure-prone components in washdown environments.

Gearboxes should use:

High-quality shaft seals rated for washdown

Multiple sealing stages where possible

Sealed fasteners and plugs

Poor sealing allows water and chemicals to enter the gearbox, contaminating lubricant and damaging bearings.

Breathers and Pressure Equalization

Standard open breathers allow moisture to enter during washdown or cooling cycles.

Washdown-rated gearboxes use:

Sealed or pressure-equalizing breathers

Hygienic breather designs

These prevent moisture ingress while allowing pressure relief.

Lubrication Requirements

Washdown environments often require food-grade lubricants.

Lubricants must:

Meet NSF H1 or H2 standards when required

Maintain viscosity in wet and temperature-variable conditions

Resist washout and emulsification

Incorrect lubricant selection accelerates wear and increases contamination risk.

Corrosion Resistance

Water and cleaning chemicals attack exposed metal surfaces.

Corrosion resistance is achieved through:

Stainless steel components

Protective coatings

Proper material selection for shafts and fasteners

Corrosion compromises seals, bearings, and structural integrity.

Mounting Orientation and Drainage

Gearboxes should be mounted to allow water to drain away naturally.

Sloped surfaces and proper orientation reduce standing water and prevent contamination buildup.

Common Gearbox Types Used in Washdown Environments

Several gearbox designs are commonly used in washdown applications.

Stainless Steel Gearboxes

Stainless steel gearboxes offer maximum corrosion resistance and cleanability.

They are commonly used in:

High-sanitation food processing

Pharmaceutical production

Dairy and meat processing

Helical and Helical-Bevel Gearboxes

These designs provide efficient, smooth operation and are available in washdown-rated configurations.

They are commonly used for conveyors and auxiliary equipment.

Shaft-Mounted Gearboxes

Shaft-mounted designs reduce alignment components but must be carefully sealed and protected for washdown use.

Planetary Gearboxes

Planetary gearboxes are used when high torque and compact size are required.

Washdown-rated planetary units must have robust sealing and corrosion protection.

Common Gearbox Failures in Washdown Environments

Washdown gearbox failures often follow predictable patterns.

Seal Failure

High-pressure water damages shaft seals.

Once seals fail, water enters the gearbox and contaminates lubricant.

Lubricant Contamination

Water ingress causes lubricant emulsification and loss of film strength.

Contaminated lubricant accelerates bearing and gear wear.

Corrosion Damage

Corrosion attacks housings, shafts, bearings, and fasteners.

Corrosion often begins at seals and progresses internally.

Bearing Failure

Water and chemical exposure degrade bearing surfaces.

Bearing failure leads to noise, vibration, and secondary gear damage.

Thermal Stress

Frequent washdowns followed by operation cause thermal cycling.

Temperature changes create pressure differentials that draw moisture into the gearbox.

Early Warning Signs of Washdown Gearbox Problems

Washdown gearbox failures often provide early indicators.

Common warning signs include:

Milky or cloudy lubricant

Oil leaks after washdown

Corrosion around seals or fasteners

Increased noise or vibration

Rising operating temperature

Prompt attention prevents catastrophic failure.

Best Practices for Preventing Washdown Gearbox Failures

Reliability improves significantly with proper selection and maintenance.

Best practices include:

Selecting gearboxes designed specifically for washdown environments

Using appropriate food-grade or washdown-rated lubricants

Inspecting seals regularly

Replacing breathers with sealed designs

Monitoring lubricant condition

Training cleaning crews to avoid direct high-pressure spray at seals

Preventive maintenance is critical in washdown applications.

When to Upgrade or Replace a Washdown Gearbox

A gearbox should be upgraded or replaced when:

Corrosion becomes persistent

Lubricant contamination is frequent

Seal failures occur repeatedly

Sanitation requirements increase

Downtime impacts production or compliance

Replacing a standard gearbox with a washdown-rated unit often dramatically improves reliability.

Final Thoughts

Washdown environments place extreme demands on gearboxes, requiring specialized design, materials, and sealing.

Most failures result from seal damage, moisture ingress, corrosion, or improper lubrication.

Selecting a gearbox specifically designed for washdown conditions helps protect equipment, improve uptime, and maintain sanitary compliance.

If you need help selecting or troubleshooting a gearbox for a washdown environment, IndustrialGearboxSupply.com can help guide you toward the right solution.