Gearboxes for Food & Beverage Applications

Food and beverage processing places some of the most demanding and specialized requirements on industrial gearboxes. In addition to mechanical performance, these applications require strict compliance with sanitation, safety, and regulatory standards. Selecting the wrong gearbox can lead to contamination risks, excessive downtime, and regulatory issues.

This article explains how to select gearboxes for food and beverage applications and highlights the most common failure modes seen in processing environments.

Why Food & Beverage Gearbox Selection Is Different

Unlike many industrial environments, food and beverage facilities require equipment that is both mechanically reliable and hygienic.

Key characteristics of food and beverage applications include:

Washdown environments

Strict sanitation requirements

Corrosive cleaning chemicals

Continuous or extended operation

Moderate to high torque demands

Compliance with food safety regulations

Gearboxes must be designed to withstand these conditions without compromising performance or safety.

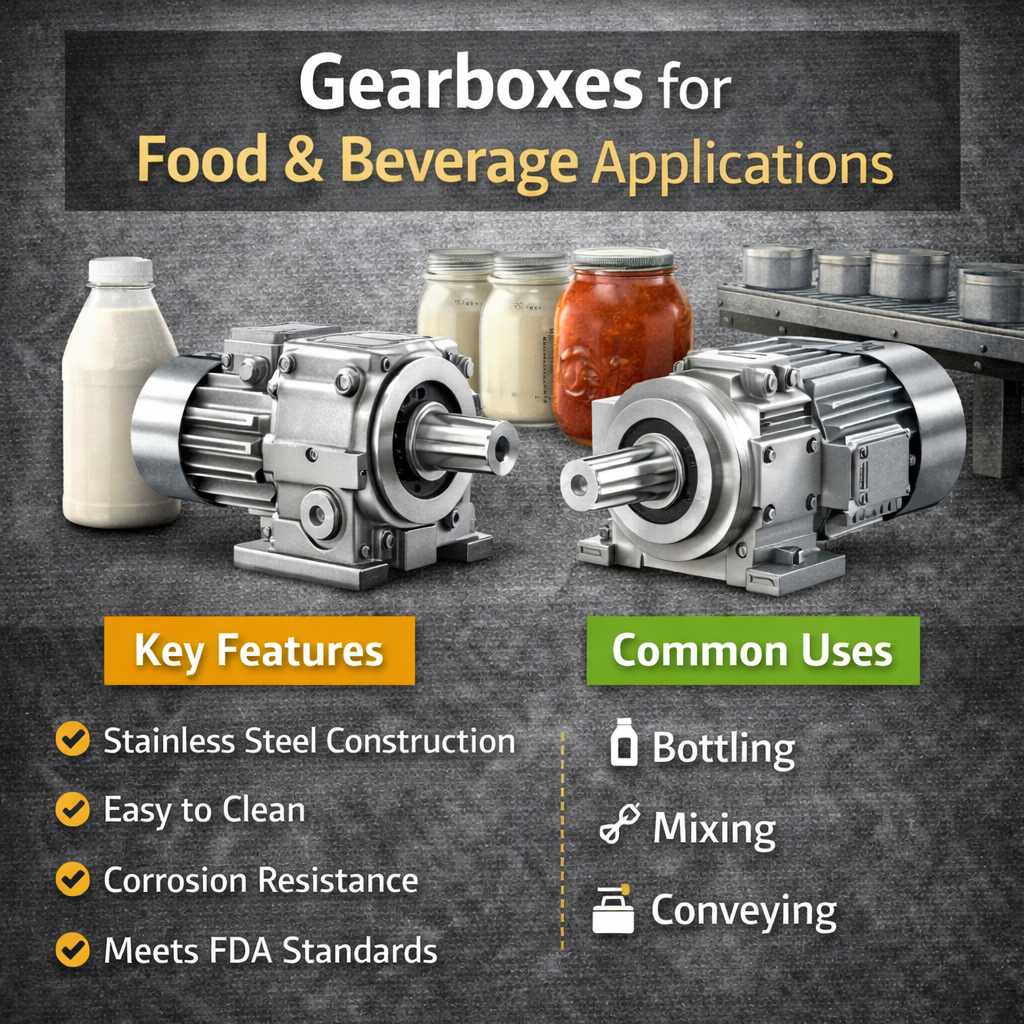

Common Food & Beverage Applications Using Gearboxes

Gearboxes are used throughout food and beverage processing lines, including:

Conveyors and material handling systems

Mixers and agitators

Fillers, cappers, and packaging equipment

Bottling and canning lines

Grinders, slicers, and cutters

Each application presents different load, speed, and hygiene challenges.

Key Gearbox Selection Factors for Food & Beverage Applications

Selecting the right gearbox requires balancing mechanical performance with sanitary design.

Sanitary Design and Cleanability

Food-grade gearboxes are designed with smooth surfaces, minimal crevices, and rounded edges to prevent bacteria buildup.

Design features often include:

Smooth housings

Sealed fasteners

Sloped surfaces for drainage

Minimal exposed threads

These features make cleaning easier and more effective.

Housing Materials

Material selection is critical in washdown environments.

Common housing materials include:

Stainless steel for corrosive or high-sanitation areas

Aluminum with protective coatings for lighter washdown applications

Specialized food-grade coatings on cast iron housings

Material choice affects corrosion resistance, durability, and cost.

Lubrication Requirements

Food and beverage gearboxes often require food-grade lubricants.

Lubricants must:

Meet NSF H1 or H2 requirements

Maintain viscosity under washdown conditions

Provide adequate protection under load

Incorrect lubricant selection can lead to premature wear or contamination risks.

Sealing and Protection

Seals must prevent both lubricant leakage and ingress of water or cleaning chemicals.

High-quality seals and proper breather design are essential to maintain gearbox integrity.

Torque, Speed, and Duty Cycle

While many food processing applications involve moderate loads, others require high torque and continuous duty.

Gearboxes must be sized for:

Starting torque

Continuous operation

Shock loading from product flow or jams

Undersizing leads to overheating and premature failure.

Gearbox Types Commonly Used in Food & Beverage Applications

Several gearbox designs are well suited for sanitary environments.

Helical Gearboxes

Helical gearboxes are widely used for conveyors and auxiliary drives.

They provide:

High efficiency

Smooth operation

Reliable performance

Bevel and Helical-Bevel Gearboxes

Bevel gearboxes are used when right-angle power transmission is required.

They are common in compact layouts and overhead conveyor systems.

Planetary Gearboxes

Planetary gearboxes are used for high-torque applications in compact spaces.

They are often selected for mixers, agitators, and heavy-duty processing equipment.

Shaft-Mounted Gearboxes

Shaft-mounted designs are popular in conveyor applications due to their simplicity and ease of installation.

They must be carefully selected for washdown environments.

Common Gearbox Failures in Food & Beverage Processing

Food and beverage gearbox failures often stem from environmental exposure.

Corrosion

Exposure to moisture and cleaning chemicals causes corrosion of housings, shafts, and fasteners.

Corrosion weakens components and compromises seals.

Seal Failures

Frequent washdowns place stress on seals.

Seal failure leads to lubricant loss and contamination risks.

Lubrication Breakdown

Washdown conditions and temperature fluctuations degrade lubricants.

Improper lubricant selection accelerates wear and reduces gearbox life.

Bearing Failures

Contamination and corrosion often lead to bearing damage.

Bearing failures increase noise, vibration, and heat.

Thermal Overload

Continuous operation combined with poor heat dissipation leads to overheating.

Overheating accelerates lubricant breakdown and component wear.

Early Warning Signs of Gearbox Issues in Food & Beverage Applications

Food and beverage gearboxes often provide early warning signs before failure.

Common indicators include:

Oil leaks or lubricant discoloration

Increased noise or vibration

Rising operating temperature

Corrosion on housing or fasteners

Reduced processing efficiency

Early detection helps prevent downtime and contamination risks.

Preventing Gearbox Failures in Food & Beverage Facilities

Preventive measures significantly improve gearbox reliability.

Best practices include:

Selecting gearboxes designed for sanitary environments

Using approved food-grade lubricants

Maintaining seals and breathers

Performing routine inspections

Monitoring temperature and vibration

Training maintenance staff on sanitation procedures

Preventive maintenance reduces downtime and extends equipment life.

When to Upgrade or Replace a Food & Beverage Gearbox

A gearbox should be upgraded or replaced when:

Sanitation requirements change

Corrosion becomes persistent

Failures occur frequently

Throughput or torque requirements increase

Regulatory compliance is compromised

Replacing a non-sanitary gearbox with a purpose-built food-grade unit often improves reliability and compliance.

Final Thoughts

Food and beverage applications require gearboxes that combine mechanical reliability with strict sanitary design.

Most gearbox failures in these environments result from corrosion, seal failure, or improper lubrication.

Understanding application requirements and selecting the right gearbox helps ensure safe, reliable, and compliant operation.

If you need help selecting or troubleshooting a gearbox for food and beverage applications, IndustrialGearboxSupply.com can help guide you toward the right solution.