How Contamination Causes Gearbox Failure

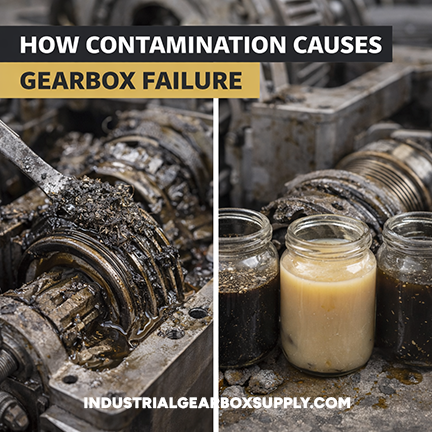

Contamination is one of the leading causes of industrial gearbox failure. Even small amounts of dirt, water, metal debris, or process contaminants can dramatically shorten gearbox life by damaging gears, bearings, seals, and lubricant.

In many cases, contamination-related failure develops slowly and goes unnoticed until performance drops, overheating occurs, or catastrophic failure happens. Understanding how contamination enters a gearbox and how it causes damage is essential for preventing premature failure.

This guide explains how contamination causes gearbox failure, the warning signs to watch for, and how to prevent it.

What Is Gearbox Contamination?

Gearbox contamination refers to any unwanted material present in the lubricant or internal components of the gearbox.

Common contaminants include dust, dirt, sand, moisture, water, metal wear particles, sludge, and chemical residues. These contaminants interfere with proper lubrication and accelerate internal wear.

Even gearboxes operating in seemingly clean environments are vulnerable to contamination over time.

How Contamination Enters a Gearbox

Breathers and Vents

Breathers allow pressure equalization inside the gearbox as temperature changes. If breathers are damaged, clogged, or unfiltered, they can draw contaminants directly into the gearbox during cooling cycles.

Poor breather design is a major contamination entry point.

Seal Degradation

Worn or damaged seals allow contaminants to enter while lubricant leaks out.

Vibration, misalignment, shaft movement, and heat accelerate seal wear. Once seals degrade, contamination exposure increases rapidly.

Improper Maintenance Practices

Contamination often enters during oil changes or maintenance.

Dirty tools, unclean containers, open housings, or incorrect storage of lubricants introduce contaminants directly into the gearbox. Even new oil can be contaminated if handled improperly.

Environmental Exposure

Dusty, wet, washdown, mining, aggregate, food processing, and outdoor environments greatly increase contamination risk.

Gearboxes exposed to moisture or temperature fluctuations are especially vulnerable to water ingress and condensation.

Types of Contamination and Their Effects

Solid Particle Contamination

Dirt, dust, and metal particles act as abrasives inside the gearbox.

These particles scratch gear teeth and bearing surfaces, increasing friction and accelerating wear. Abrasive contamination rapidly destroys the protective lubricant film.

Water Contamination

Water is extremely damaging to gearboxes.

Moisture reduces lubricant film strength, promotes corrosion, accelerates oxidation, and causes additive depletion. Water contamination also leads to foaming, poor lubrication, and bearing failure.

Even small amounts of water significantly reduce lubricant life.

Wear Debris Contamination

As components wear, they generate metal particles that circulate in the oil.

These particles further accelerate wear by creating a self-reinforcing damage cycle. Without filtration or oil changes, wear debris quickly escalates internal damage.

Chemical and Process Contaminants

Certain industrial environments expose gearboxes to chemicals, solvents, or process residues.

These substances can degrade lubricant additives, attack seals, and reduce lubrication effectiveness.

How Contamination Causes Gearbox Failure

Contamination disrupts the lubricant’s ability to form a protective film between metal surfaces.

As friction increases, gears and bearings experience metal-to-metal contact. Heat builds up, accelerating lubricant breakdown and internal wear.

Over time, contamination leads to pitting, scoring, bearing spalling, overheating, efficiency loss, seal failure, and ultimately catastrophic gearbox failure.

Warning Signs of Contamination-Related Failure

Contamination-related gearbox failure often presents early warning signs.

Common symptoms include darkened or cloudy oil, foaming, sludge formation, rising operating temperature, increased noise, vibration, declining efficiency, and frequent seal leaks.

Ignoring these signs allows damage to progress rapidly.

How to Detect Contamination Early

Oil analysis is one of the most effective tools for detecting contamination.

Oil analysis can identify particle levels, water content, oxidation, and wear metals before failure occurs. Visual oil inspection can also reveal obvious contamination issues.

Monitoring temperature, vibration, and noise trends helps confirm contamination-related problems.

Preventing Contamination in Industrial Gearboxes

Preventing contamination is far more cost-effective than repairing contamination damage.

Use proper breathers and filters to control airborne contamination. Maintain seals and replace them at the first signs of wear.

Follow clean maintenance practices during oil changes. Store lubricants in sealed, clean containers and use dedicated tools.

Change oil at proper intervals and use oil analysis to optimize service schedules.

Protect gearboxes from harsh environmental exposure whenever possible.

When Contamination Means Replacement Is Necessary

In some cases, contamination damage is too advanced to repair economically.

Replacement should be considered when gear and bearing surfaces are severely damaged, corrosion is extensive, or contamination has caused recurring failures.

Selecting a properly sealed and correctly specified replacement gearbox helps prevent future contamination issues.

Final Thoughts

Contamination is a silent but destructive cause of gearbox failure. Dirt, water, and wear debris gradually destroy lubrication, accelerate wear, and lead to overheating and breakdown.

Understanding how contamination enters a gearbox and taking steps to prevent it can significantly extend gearbox life and reduce downtime.

If you need help evaluating contamination-related gearbox issues or selecting the right lubrication and sealing solutions, IndustrialGearboxSupply.com can help guide you toward the right solution.