How Long Do Industrial Gearboxes Last?

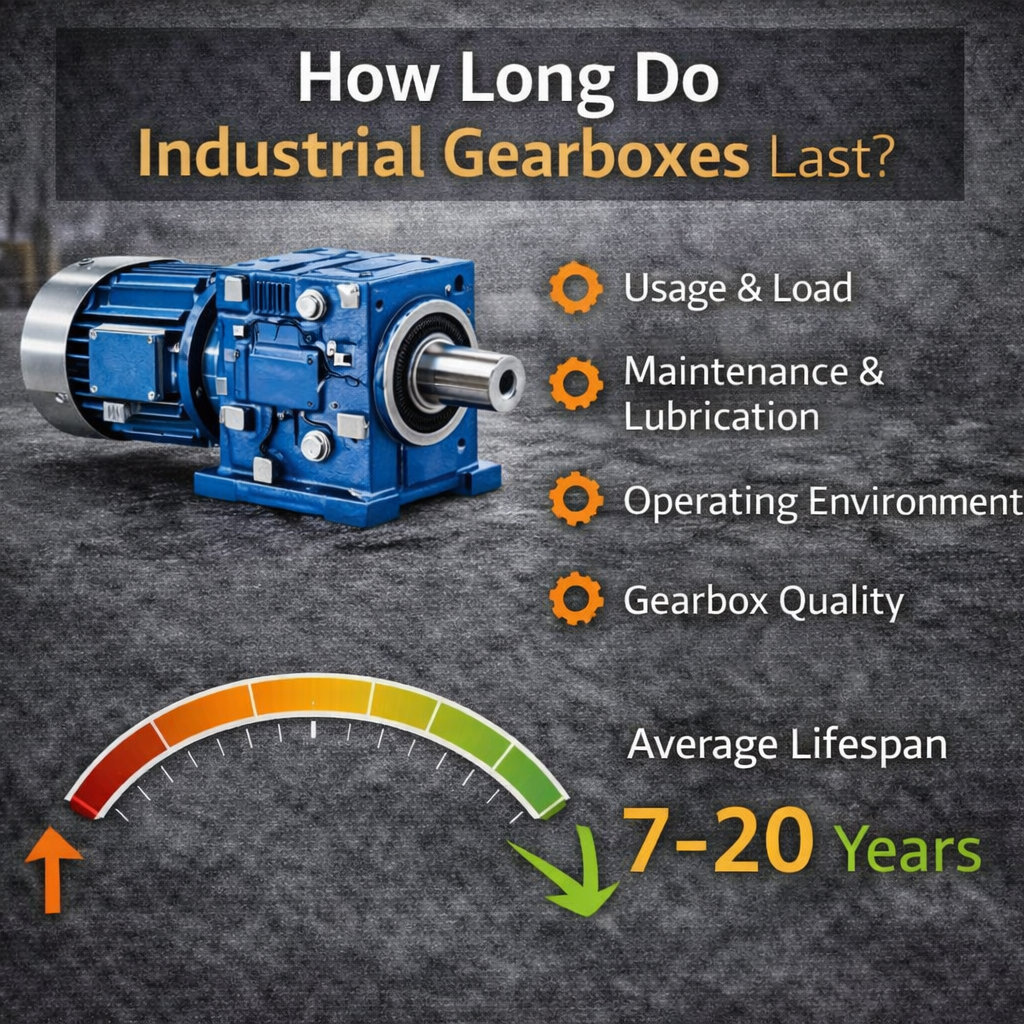

One of the most common questions asked by plant managers and maintenance teams is how long an industrial gearbox should last. The short answer is: it depends. Gearbox lifespan varies widely based on application, load conditions, maintenance practices, and operating environment.

This article explains what determines gearbox life expectancy, realistic service life ranges, and how to extend the life of an industrial gearbox.

Typical Lifespan of an Industrial Gearbox

Under ideal conditions, many industrial gearboxes are designed to last 20 to 30 years. In real-world applications, service life is often shorter.

Typical lifespan ranges include:

Light-duty applications: 15–30 years

Moderate-duty industrial use: 10–20 years

Heavy-duty or shock-load applications: 5–15 years

Poorly maintained or misapplied gearboxes: Less than 5 years

These ranges assume the gearbox is properly selected, installed, lubricated, and maintained.

What Determines How Long a Gearbox Lasts

Gearbox life is influenced by multiple factors working together.

Application Load and Service Factor

The most significant factor affecting gearbox life is load.

Gearboxes that operate:

Near or above rated torque

Under frequent shock loads

With inadequate service factor

will experience accelerated wear. Undersized gearboxes fail far sooner than properly sized units.

Duty Cycle and Operating Hours

Gearboxes designed for intermittent duty will not last as long if operated continuously.

Key considerations include:

Hours of operation per day

Number of starts and stops

Reversing operation

Variable speed operation

Higher duty cycles reduce gearbox life unless accounted for during selection.

Lubrication Quality and Maintenance

Lubrication plays a critical role in gearbox longevity.

Gearboxes last significantly longer when:

Correct lubricant type and viscosity are used

Oil is changed at recommended intervals

Contamination is controlled

Oil condition is monitored

Lubrication failures are one of the leading causes of premature gearbox failure.

Installation and Alignment

Improper installation dramatically shortens gearbox life.

Common installation-related issues include:

Misalignment

Improper mounting orientation

Incorrect torque on fasteners

Poor foundation support

Even small alignment errors can reduce bearing and gear life by years.

Operating Environment

Environmental conditions strongly affect gearbox lifespan.

Harsh environments include:

Washdown or high-moisture areas

Dusty or abrasive locations

Extreme temperatures

Corrosive chemicals

Gearboxes not designed for their environment deteriorate quickly.

Overhung and Axial Loads

External loads from belts, chains, or sprockets place additional stress on bearings and shafts.

If overhung or axial loads exceed gearbox ratings, bearing life is significantly reduced.

Quality of Design and Manufacturing

Gearbox lifespan also depends on:

Gear material and heat treatment

Bearing quality

Housing rigidity

Manufacturing tolerances

Higher-quality gearboxes generally last longer under similar conditions.

Common Reasons Gearboxes Fail Early

Most gearboxes that fail prematurely do so for predictable reasons.

Common causes include:

Undersizing

Ignoring peak or shock loads

Poor lubrication practices

Contamination

Overheating

Misalignment

Seal failures

Repeated overload events

Addressing these factors can dramatically extend service life.

Signs a Gearbox Is Reaching the End of Its Life

Gearboxes rarely fail without warning.

Common end-of-life indicators include:

Rising operating temperature

Increased noise or vibration

Metal particles in oil

Frequent oil leaks

Decreasing efficiency

Repeated bearing or seal failures

Early detection allows planned replacement instead of emergency downtime.

Can Gearbox Life Be Extended?

Yes, gearbox life can often be extended significantly.

Effective strategies include:

Proper sizing and service factor selection

Routine oil analysis

Scheduled oil changes

Monitoring temperature and vibration

Maintaining seals and breathers

Correct alignment and mounting

Avoiding overload conditions

Preventive maintenance is far less expensive than unplanned failure.

Repair, Rebuild, or Replace?

As gearboxes age, maintenance decisions become critical.

Repair may be sufficient for minor bearing or seal issues.

Rebuild can extend life if gears and housings remain in good condition.

Replacement is often the best option when internal damage is severe or failures are recurring.

Total cost of ownership should guide the decision.

Planning for Gearbox Replacement

Understanding expected gearbox life allows better planning.

Best practices include:

Tracking gearbox age and operating hours

Monitoring performance trends

Planning replacements during scheduled shutdowns

Stocking critical spares for high-risk applications

Proactive planning reduces downtime and cost.

Final Thoughts

Industrial gearboxes can last decades when properly selected, installed, and maintained. Most premature failures are not caused by poor equipment quality, but by misapplication, inadequate lubrication, or lack of maintenance.

Understanding what affects gearbox lifespan helps you make better decisions, reduce downtime, and extend equipment life.

If you need help evaluating the condition or remaining life of an industrial gearbox, IndustrialGearboxSupply.com can help assess your situation and recommend the best path forward.