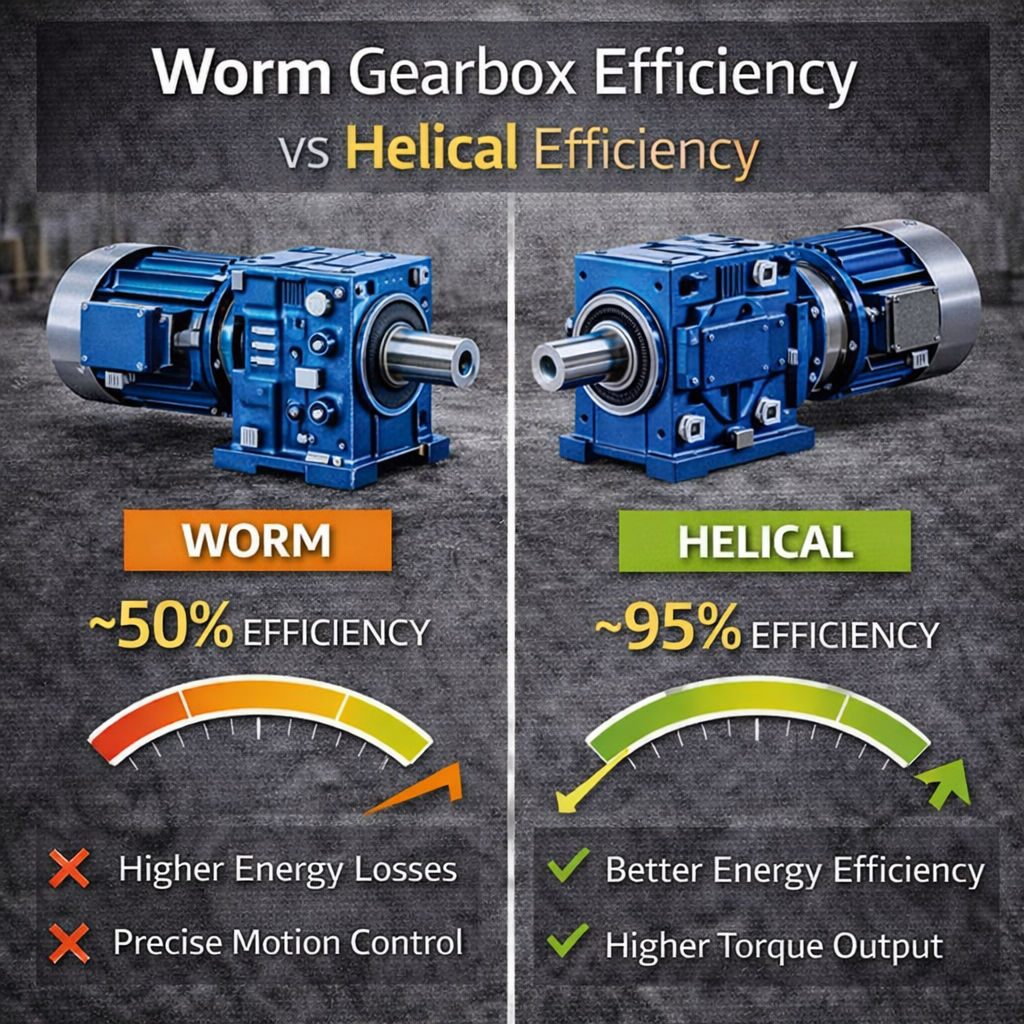

Worm Gearbox Efficiency vs Helical Efficiency

Efficiency is a critical factor when selecting an industrial gearbox. Two of the most commonly compared designs are worm gearboxes and helical gearboxes. While both are widely used, their efficiency characteristics are very different and can significantly impact energy consumption, heat generation, and long-term operating cost.

This article compares worm gearbox efficiency and helical gearbox efficiency to help you choose the right solution for your application.

How Gearbox Efficiency Is Defined

Gearbox efficiency refers to how much input power is delivered as usable output power.

Efficiency losses occur due to:

Gear tooth friction

Sliding versus rolling contact

Bearing losses

Lubrication shear

Heat generation

Higher efficiency means less energy lost as heat and lower operating costs.

Worm Gearbox Efficiency Explained

Worm gearboxes use a worm (screw) that drives a worm wheel. Power transfer occurs primarily through sliding contact rather than rolling contact.

Typical Worm Gearbox Efficiency

Worm gearbox efficiency typically ranges from:

50% to 90%, depending on ratio and design

Lower ratios may approach higher efficiency, while higher reduction ratios result in significantly lower efficiency.

Why Worm Gearboxes Are Less Efficient

Efficiency losses in worm gearboxes are caused by:

High sliding friction between worm and wheel

Increased heat generation

Lubricant shear losses

As ratio increases, sliding contact increases, further reducing efficiency.

Advantages Despite Lower Efficiency

Despite lower efficiency, worm gearboxes offer unique benefits:

Compact right-angle design

Smooth, quiet operation

Shock absorption

Self-locking characteristics in some ratios

These advantages make worm gearboxes suitable for specific applications despite efficiency limitations.

Helical Gearbox Efficiency Explained

Helical gearboxes use angled gear teeth that mesh gradually, allowing rolling contact between gear surfaces.

Typical Helical Gearbox Efficiency

Helical gearbox efficiency typically ranges from:

94% to 98% per gear stage

Multi-stage helical gearboxes maintain high overall efficiency even at higher reduction ratios.

Why Helical Gearboxes Are More Efficient

Helical gearboxes achieve higher efficiency because:

Power transfer occurs through rolling contact

Reduced friction between gear teeth

Lower heat generation

More efficient lubrication behavior

This makes helical gearboxes ideal for continuous-duty applications.

Efficiency Comparison by Application

Continuous-Duty Applications

Helical gearboxes are far superior in continuous-duty applications due to lower energy losses and reduced heat buildup.

Worm gearboxes may overheat or suffer accelerated wear under continuous operation.

Intermittent or Low-Duty Applications

Worm gearboxes can perform well in intermittent-duty applications where efficiency losses are less critical.

Infrequent operation allows heat to dissipate between cycles.

High Reduction Ratios

For high reduction ratios:

Worm gearboxes offer compact solutions but lower efficiency

Helical gearboxes require multiple stages but maintain higher efficiency

Energy costs over time often favor helical designs.

Heat Generation and Thermal Limits

Efficiency losses translate directly into heat.

Worm gearboxes:

Generate significantly more heat

Require careful thermal management

May need oversized housings or external cooling

Helical gearboxes:

Operate cooler

Handle higher continuous loads

Offer longer lubricant and component life

Heat is a major factor in gearbox reliability.

Energy Cost Considerations

Lower efficiency leads to higher energy consumption.

Over time:

Worm gearboxes can significantly increase operating costs

Helical gearboxes reduce energy use and heat-related failures

In energy-intensive operations, efficiency differences can outweigh initial cost savings.

Load and Shock Handling

Helical gearboxes handle shock loads better due to rolling contact and robust gear geometry.

Worm gearboxes:

Absorb shock well at low speeds

Can suffer accelerated wear under repeated heavy loads

Application severity should guide selection.

Maintenance and Service Life Impact

Efficiency affects service life.

Worm gearboxes:

Require more frequent oil changes

Are more sensitive to lubrication quality

Experience faster wear under continuous load

Helical gearboxes:

Offer longer service intervals

Provide more consistent performance over time

Maintenance costs often favor helical designs.

When a Worm Gearbox Makes Sense

A worm gearbox may be the right choice when:

Compact right-angle layout is required

Low speed operation is acceptable

Self-locking is beneficial

Duty cycle is light or intermittent

Efficiency is not the primary concern

When a Helical Gearbox Is the Better Choice

A helical gearbox is usually the better choice when:

High efficiency is required

Continuous-duty operation is expected

Energy costs matter

Long service life is critical

Heat generation must be minimized

Final Thoughts

Worm and helical gearboxes serve different purposes.

Worm gearboxes offer compact, quiet, right-angle solutions at the cost of efficiency, while helical gearboxes deliver superior efficiency, lower heat, and longer service life.

Understanding efficiency differences helps you choose the gearbox that delivers the best performance, reliability, and total cost of ownership for your application.

If you need help comparing worm and helical gearbox efficiency for your specific application, IndustrialGearboxSupply.com can help evaluate your requirements and recommend the right solution.