How to Calculate Gearbox Torque (Step-by-Step)

Knowing how to calculate gearbox torque is essential for selecting the right gearbox, preventing overload, and ensuring reliable performance. Torque calculations help you confirm whether a gearbox can handle your load, choose the correct service factor, and avoid common failure causes like overheating, bearing damage, and broken gear teeth.

This step-by-step guide shows the most common gearbox torque calculations used in industrial applications, along with practical examples.

What Is Gearbox Torque?

Torque is a twisting force that turns a shaft. In power transmission, torque is what actually “does the work” at the gearbox output.

Gearbox torque is typically discussed in two ways:

Input torque (torque going into the gearbox from the motor)

Output torque (torque delivered by the gearbox to the driven equipment)

Gearboxes trade speed for torque. When speed goes down, torque goes up (minus efficiency losses).

The 3 Numbers You Need

To calculate gearbox torque, you usually need:

Power (horsepower or kilowatts)

Speed (RPM)

Gear ratio (or input and output RPM)

You may also need:

Efficiency (especially for worm gearboxes)

Service factor (for real-world loading)

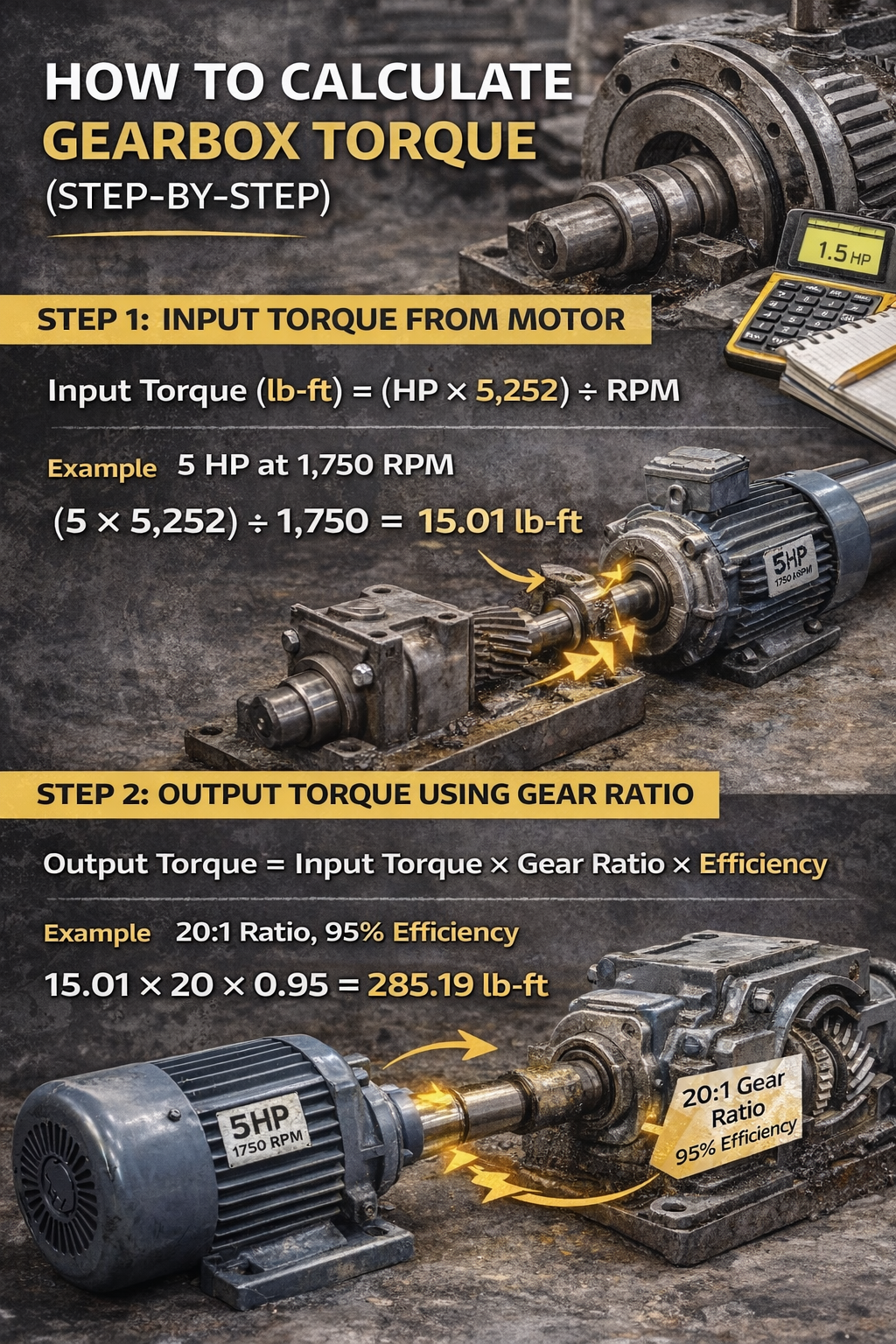

Step 1: Calculate Motor Input Torque From Horsepower and RPM

If you have horsepower and motor RPM, use this formula:

Input Torque (lb-in) = (HP × 63,025) ÷ RPM

Or if you prefer lb-ft:

Input Torque (lb-ft) = (HP × 5,252) ÷ RPM

Example

Motor = 5 HP at 1,750 RPM

Input torque (lb-ft) = (5 × 5,252) ÷ 1,750

= 26,260 ÷ 1,750

= 15.01 lb-ft (approx.)

Step 2: Calculate Output Torque Using Gear Ratio

Once you have input torque, multiply by the gear ratio and efficiency.

Output Torque = Input Torque × Gear Ratio × Efficiency

Efficiency is usually:

Helical / bevel: ~0.94 to 0.98

Planetary: ~0.95 to 0.98

Worm: can be much lower depending on ratio and design (~0.50 to 0.90)

Example

Using the same 5 HP motor, with a 20:1 gearbox and 95% efficiency (0.95):

Output torque (lb-ft) = 15.01 × 20 × 0.95

= 15.01 × 19

= 285.19 lb-ft (approx.)

Step 3: Calculate Output Torque Directly From Output RPM

If you know output RPM instead of gear ratio, you can calculate output torque directly from horsepower:

Output Torque (lb-ft) = (HP × 5,252 × Efficiency) ÷ Output RPM

Example

5 HP gearbox output speed = 87.5 RPM (which matches a 20:1 ratio from 1,750 RPM)

Efficiency = 0.95

Output torque (lb-ft) = (5 × 5,252 × 0.95) ÷ 87.5

= (26,260 × 0.95) ÷ 87.5

= 24,947 ÷ 87.5

= 285.11 lb-ft (approx.)

Step 4: Convert Torque Units (Common Conversions)

Many gearboxes list torque in Nm instead of lb-ft.

1 lb-ft = 1.356 Nm

1 Nm = 0.7376 lb-ft

1 lb-in = 0.113 lb-ft

Example

285 lb-ft × 1.356 = 386.5 Nm (approx.)

Step 5: Apply Service Factor for Real-World Loads

Torque calculations above are “ideal.” Real applications have shock loads, starts/stops, and duty cycle stress.

That’s why gearboxes use a service factor (SF).

Required Torque = Calculated Output Torque × Service Factor

Common service factors:

Light duty: 1.0–1.25

Moderate duty: 1.25–1.5

Heavy shock/reversing: 1.75–2.0+

Example

Output torque = 285 lb-ft

Service factor = 1.5

Required torque rating = 285 × 1.5 = 427.5 lb-ft

Your gearbox should be rated above 427.5 lb-ft for that application.

Step 6: Check Gearbox Output Shaft and Coupling Ratings

Even if gearbox torque rating is sufficient, the output shaft and coupling must also handle the torque.

Always verify:

Output shaft size and material rating

Keyway rating

Coupling rating

Mounting rigidity and alignment

Underrated couplings and misalignment often cause failures even when torque calculations are correct.

Common Mistakes When Calculating Gearbox Torque

Ignoring efficiency (especially on worm gearboxes)

Using motor nameplate HP when the motor is oversized or underloaded

Forgetting service factor

Confusing lb-in and lb-ft

Using “ratio” without confirming true output RPM under load

Quick Torque Calculation Summary

Input torque from motor:

T_in (lb-ft) = (HP × 5,252) ÷ RPMOutput torque from ratio:

T_out = T_in × Ratio × EfficiencyOutput torque from output RPM:

T_out (lb-ft) = (HP × 5,252 × Efficiency) ÷ Output RPMRequired rating with service factor:

T_required = T_out × SF

Final Thoughts

Calculating gearbox torque is the foundation of selecting the correct gearbox for industrial equipment. When torque is calculated correctly and service factor is applied, you reduce the risk of overheating, gear wear, bearing failure, and premature breakdown.

If you want help calculating gearbox torque for your exact application, IndustrialGearboxSupply.com can help you verify torque requirements and recommend the right gearbox type and size.