Industrial Gearbox Types: Choosing the Right Gearbox for Your Application

Industrial gearboxes are essential for transferring power, controlling speed, and increasing torque in machines across nearly every industry. But not all gearboxes are created equal—each type is designed with specific strengths, layouts, and load capacities in mind.

Whether you're replacing an existing gearbox, selecting a unit for a new machine, or troubleshooting a mechanical issue, understanding the different types of industrial gearboxes is key to making the right choice.

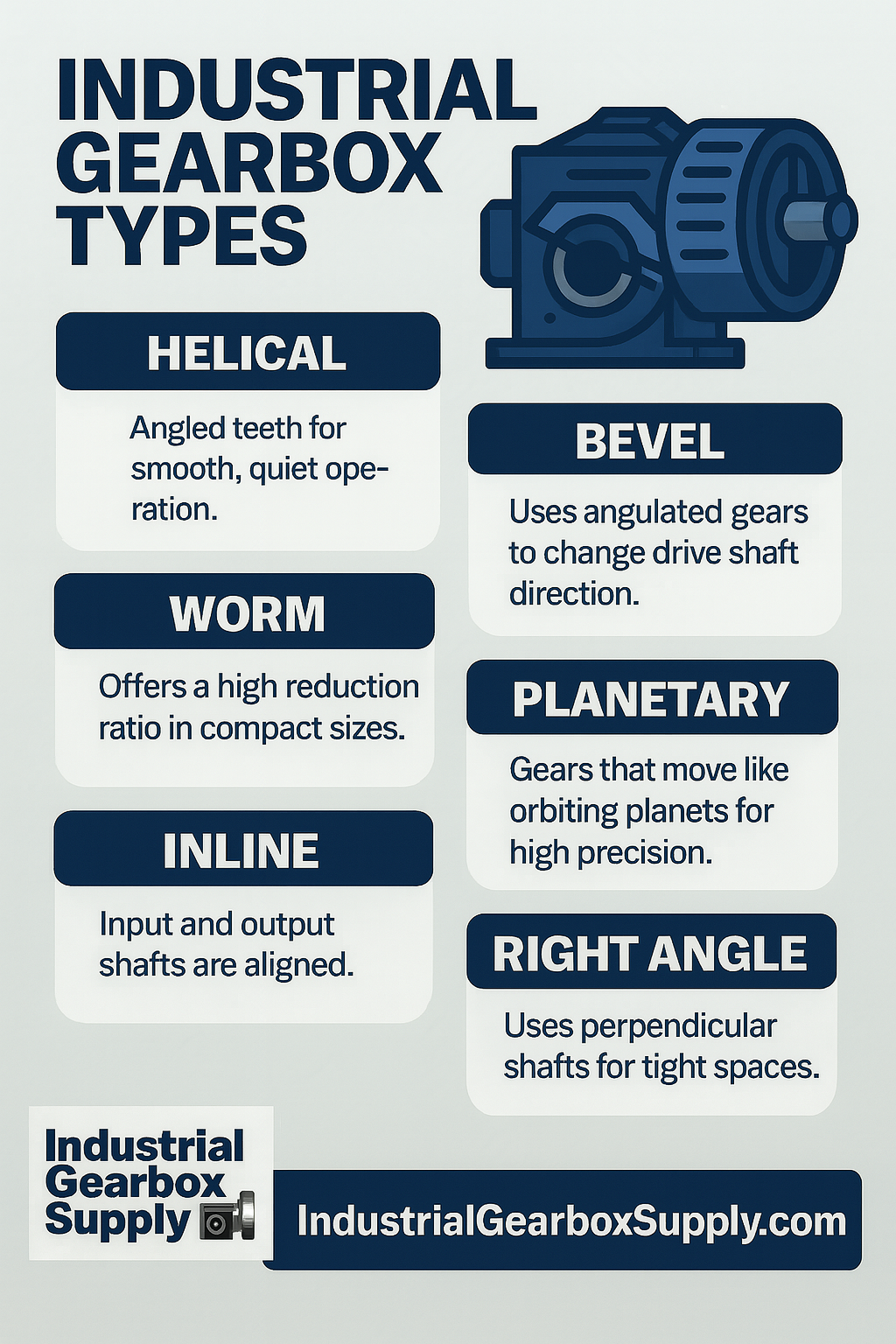

1. Helical Gearbox

Best for: Heavy-duty applications, continuous load

Common uses: Conveyors, crushers, elevators, mixers

Helical gearboxes use angled teeth that engage more gradually than straight-cut gears. This design results in smoother operation, less vibration, and quieter performance. They're ideal for continuous-load applications and are often used in parallel shaft or inline setups.

Benefits:

Quiet and efficient

Handles high torque

Long lifespan with proper maintenance

2. Bevel Gearbox

Best for: Right-angle power transmission

Common uses: Automotive, marine, packaging, mining

Bevel gearboxes change the direction of shaft rotation, usually at a 90-degree angle. They are available in straight or spiral (helical) tooth designs. Spiral bevels offer smoother engagement and higher torque capacity.

Benefits:

Ideal for changing drive direction

Precise movement

Compact, versatile design

3. Worm Gearbox

Best for: High-ratio speed reduction in compact space

Common uses: Lifts, conveyors, presses, material handling

Worm gearboxes use a worm screw meshing with a worm wheel. They provide extremely high reduction ratios in a small footprint, with the added benefit of self-locking capability (which prevents back-driving in some designs).

Benefits:

Compact size

High reduction ratios

Low noise, self-locking capability

4. Planetary Gearbox

Best for: High torque density and precise positioning

Common uses: Robotics, automation, aerospace, printing

Planetary gearboxes use a sun gear surrounded by multiple planet gears within a ring. This design distributes the load evenly, allowing for high torque transfer in a compact, lightweight form.

Benefits:

Excellent torque-to-size ratio

High precision

Used in servo systems and high-tech equipment

5. Inline Gearbox

Best for: Applications requiring straight-line power flow

Common uses: Fans, pumps, mixers, screw conveyors

An inline gearbox has input and output shafts aligned. They can house various gear types (helical, planetary, etc.) but are commonly used where simplicity and compact design are needed.

Benefits:

Easy integration

Versatile design options

Efficient torque transfer

6. Right Angle Gearbox

Best for: Tight spaces requiring perpendicular shaft orientation

Common uses: Material handling, conveyors, augers

A right angle gearbox can include bevel or worm gears to change the power flow 90 degrees. These are commonly used when space constraints prevent a straight alignment of motor and output.

Benefits:

Compact for tight installations

Flexible mounting positions

Works with various gear types

How to Choose the Right Gearbox Type

Choosing the wrong gearbox can lead to underperformance, premature wear, or system failure. Consider the following when selecting:

FactorWhat to Look ForTorqueRequired load-handling capacitySpeed RatioInput vs. desired output speedMountingHorizontal, vertical, foot, or flange mountShaft OrientationInline or right angleEnvironmentExposure to moisture, dust, temperature, or washdown dutySpace ConstraintsInline or compact models for tight areasNoise RequirementsHelical or planetary for quieter performance

Why Choose Industrial Gearbox Supply

At Industrial Gearbox Supply, we stock and supply all major industrial gearbox types with expert support to ensure you're getting the right fit for your application.

✅ Fast Shipping for stocked gear reducers

✅ Expert Support for replacements and upgrades

✅ OEM and Interchange Options

✅ Custom Builds and Mounting Solutions

Industries We Serve

Manufacturing

Agriculture

Food & Beverage

Wastewater Treatment

Material Handling

Mining & Aggregates

Pulp & Paper

Packaging & Automation

Contact Our Gearbox Experts Today

Not sure which gearbox type fits your needs? Our team can help you size, select, and source the ideal industrial gearbox for your application.

📞 Call 1-877-465-9108

🌐 Visit: https://industrialgearboxsupply.com

📧 Email: support@industrialgearboxsupply.com