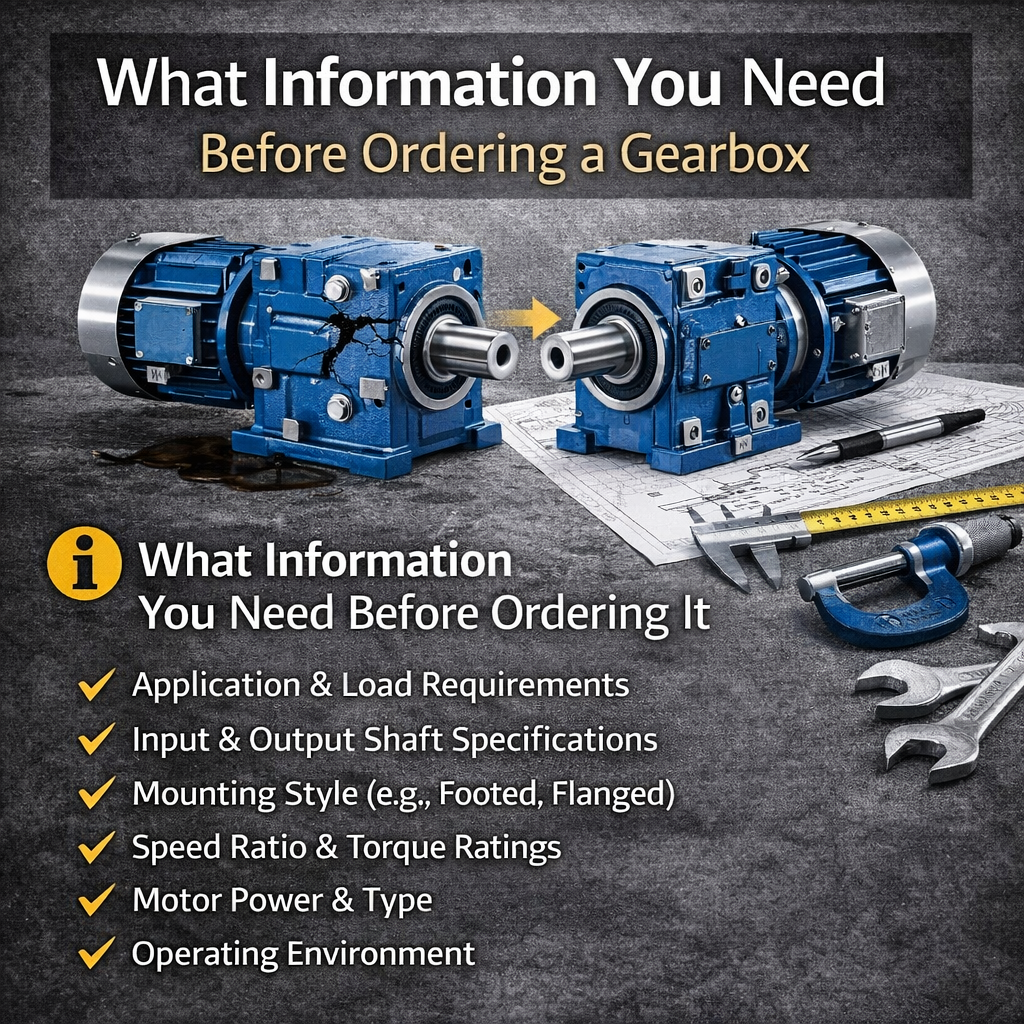

What Information You Need Before Ordering a Gearbox

Ordering a gearbox without the right information is one of the most common causes of incorrect sizing, long lead times, and premature failures. Gearboxes are not one-size-fits-all components, and small details can dramatically affect performance, reliability, and compatibility.

This article outlines exactly what information you need before ordering a gearbox so you can avoid costly mistakes and get the right unit the first time.

Why Preparation Matters When Ordering a Gearbox

Many gearbox problems start before the unit is even installed.

Incomplete or incorrect information can result in:

Undersized or oversized gearboxes

Incorrect ratios

Mounting incompatibility

Shaft mismatches

Overheating

Excessive wear

Long delays due to rework or returns

Providing accurate information upfront saves time, money, and downtime.

Required Output Speed

One of the most critical inputs is the required output speed.

You should know:

Desired output RPM

How the speed was calculated

Whether the speed is fixed or variable

Minimum and maximum operating speeds

Output speed determines gearbox ratio and directly affects torque and efficiency.

Required Torque

Torque requirements must be clearly defined.

At a minimum, you should provide:

Required running torque

Required starting torque

Peak or shock torque, if applicable

Torque should be calculated based on load, not motor nameplate alone. Many gearboxes fail because they were sized only for motor power rather than actual load conditions.

Duty Cycle and Operating Hours

How often and how long the gearbox operates matters.

Key details include:

Hours of operation per day

Continuous or intermittent duty

Number of starts and stops per hour

Reversing operation, if any

High-duty or high-cycle applications require higher service factors.

Service Factor Requirements

Service factor accounts for application severity.

You should specify:

Type of load (smooth, moderate shock, heavy shock)

Application type (conveyor, mixer, crusher, packaging, etc.)

Environmental factors

Underestimating service factor is one of the most common gearbox ordering mistakes.

Mounting Orientation

Gearboxes are designed for specific mounting positions.

Be prepared to specify:

Horizontal or vertical mounting

Shaft orientation

Whether the gearbox will be foot-mounted, flange-mounted, or shaft-mounted

Incorrect mounting can lead to lubrication and bearing failures.

Input Power and Motor Details

The gearbox must match the motor.

Provide:

Motor horsepower or kilowatt rating

Motor speed (RPM)

Motor frame size

Motor mounting type

Motor shaft dimensions

This ensures proper compatibility and alignment.

Output Shaft Details

Output shaft information is critical for proper fit.

You should know:

Shaft diameter

Shaft length

Keyway size

Hollow or solid shaft

Direction of rotation

Mismatched shaft details are a common cause of installation delays.

Overhung and Axial Loads

Many applications apply external forces to the gearbox.

You should specify:

Belt, chain, or sprocket drive details

Distance from gearbox to load

Expected overhung load

Axial thrust, if applicable

Ignoring these loads often leads to bearing failure.

Environment and Operating Conditions

Environmental conditions directly affect gearbox selection.

Important details include:

Ambient temperature range

Presence of dust, moisture, or chemicals

Washdown requirements

Indoor or outdoor operation

Corrosive or sanitary environment

Gearboxes must be designed to survive their environment.

Lubrication Requirements

Lubrication needs vary by application.

Be prepared to specify:

Oil or grease lubrication

Food-grade lubricant requirements

Ambient temperature extremes

Maintenance interval preferences

Incorrect lubricant selection shortens gearbox life.

Noise and Precision Requirements

Some applications require quiet or precise operation.

You should identify:

Maximum acceptable noise level

Backlash limits

Positioning accuracy requirements

These factors influence gearbox type selection.

Available Space and Physical Constraints

Physical fit matters as much as performance.

Provide:

Available installation space

Height, width, and length constraints

Weight limitations

Clearance requirements

Compact designs may be required in tight spaces.

Replacement vs New Installation

The ordering process differs for replacements.

You should clarify:

Whether the gearbox is replacing an existing unit

Manufacturer and model of the existing gearbox

Any performance issues with the old unit

Replacement applications often allow for drop-in alternatives or upgrades.

Lead Time Expectations

Lead time affects gearbox selection.

Be clear about:

Required delivery date

Whether downtime is critical

Availability of temporary solutions

This helps balance performance and availability.

Documentation and Compliance Requirements

Some applications require documentation.

You may need:

Certifications

Compliance with industry standards

Special labeling or materials

Providing this upfront avoids delays.

Final Checklist Before Ordering a Gearbox

Before placing an order, confirm you have:

Output speed and torque

Duty cycle and service factor

Mounting orientation

Motor and shaft details

Load conditions

Environmental requirements

Space constraints

Lead time expectations

A complete checklist ensures correct selection.

Final Thoughts

Ordering a gearbox without complete information increases the risk of failure, downtime, and additional cost.

Providing accurate, detailed information upfront allows suppliers to select or build the right gearbox for your application.

If you’re unsure about any of these details, IndustrialGearboxSupply.com can help review your application and ensure the correct gearbox is ordered the first time.